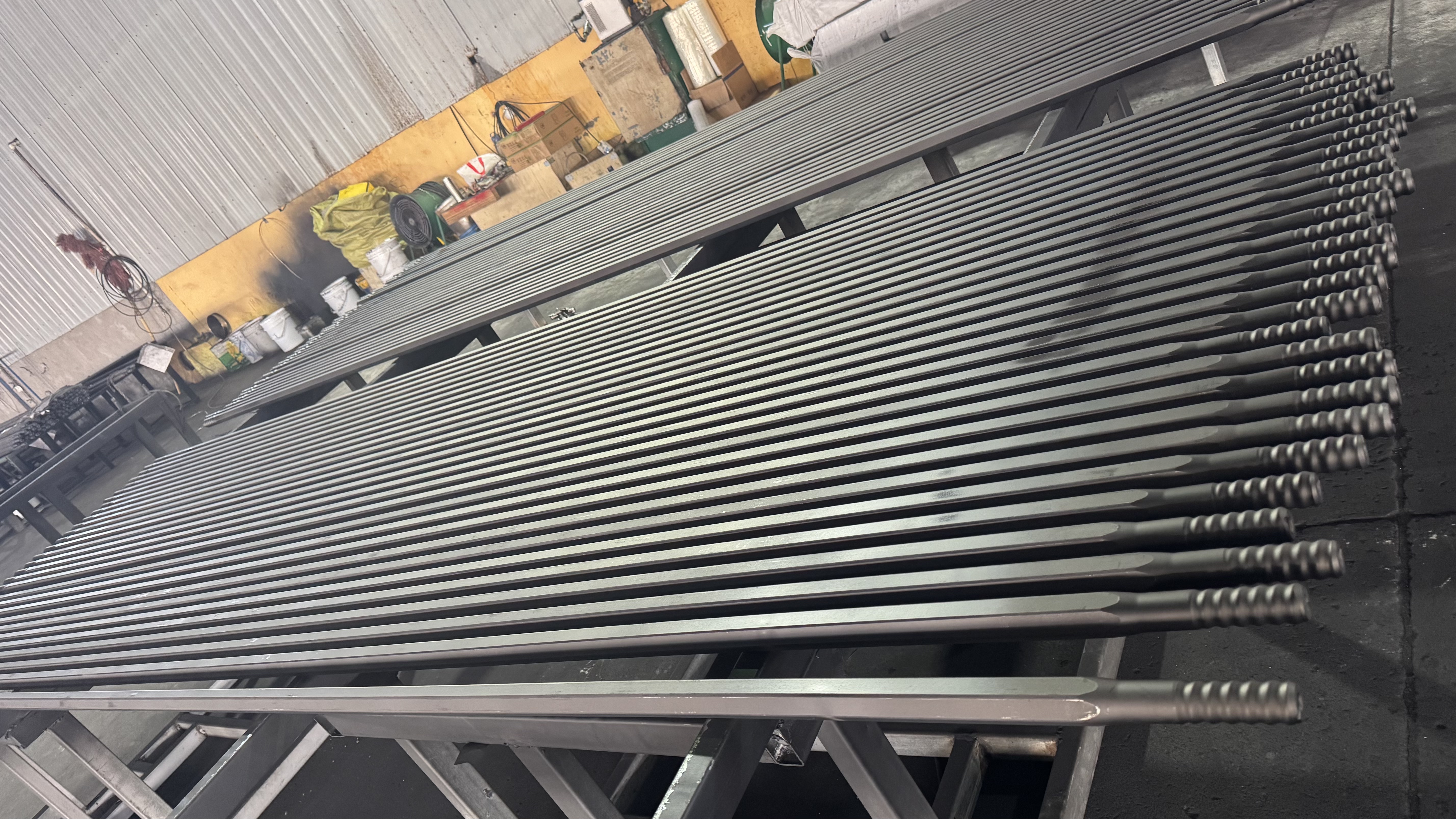

mining drill rod

Mining drill rods are essential components in the mining and exploration industry, serving as crucial tools for penetrating various geological formations to extract valuable resources. These precision-engineered tools consist of high-strength steel alloys designed to withstand extreme pressure, temperature, and abrasive conditions encountered during drilling operations. The rods feature specialized threading systems that enable secure connections between multiple sections, allowing for deep penetration into the earth's surface. Modern mining drill rods incorporate advanced metallurgical compositions that enhance durability and resistance to wear, while their optimized geometry ensures efficient transfer of rotational force and drilling fluid circulation. They come in various lengths and diameters to accommodate different drilling requirements and ground conditions. The design includes internal channels for fluid circulation, which aids in cooling the drill bit and removing debris from the borehole. These rods are manufactured with strict quality control measures to ensure consistent performance and reliability in challenging underground environments. Their versatility allows them to be used in various applications, from exploration drilling and blast hole drilling to geotechnical investigation and underground mining operations.