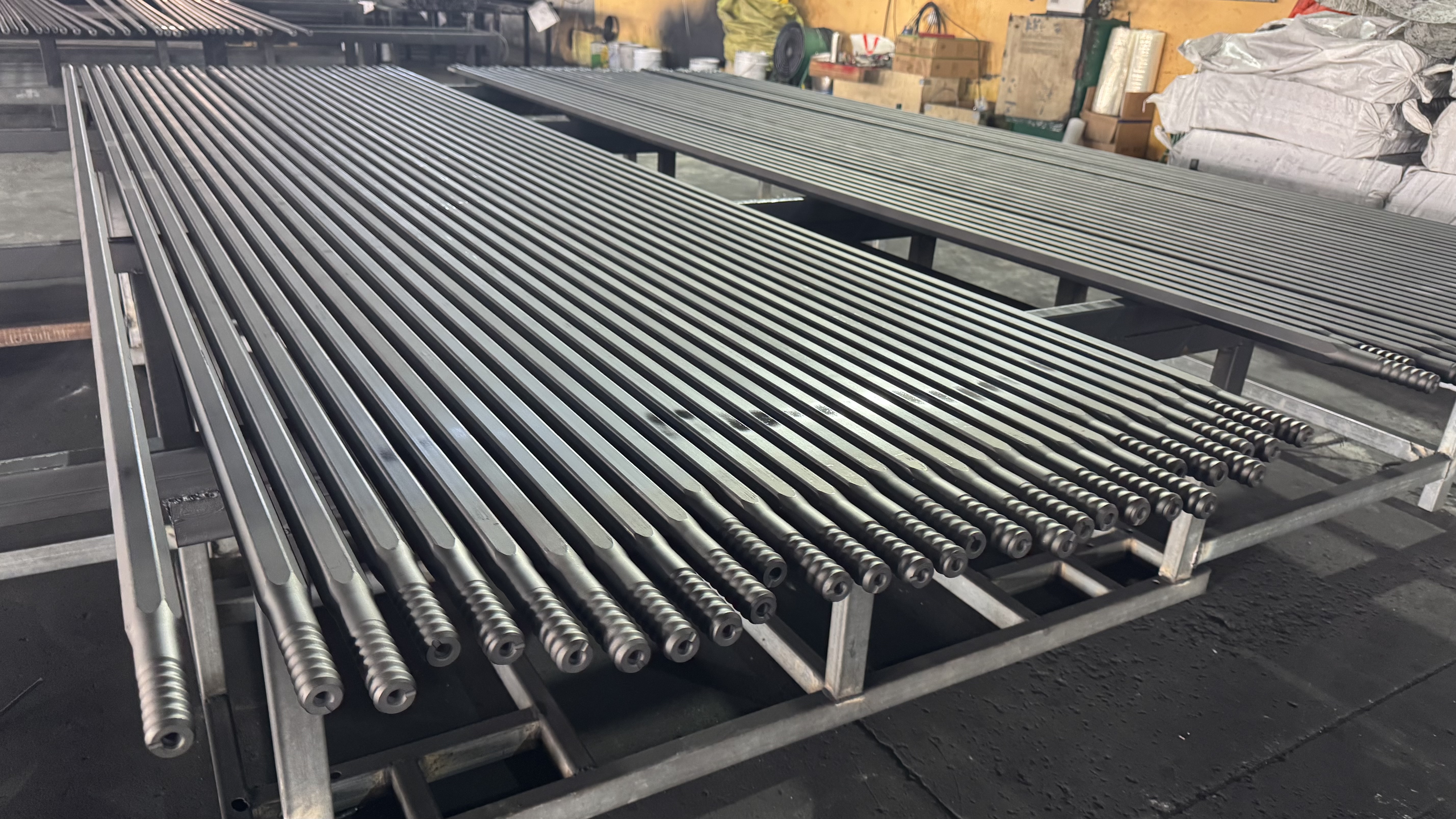

drill rod mf t45

The drill rod MF T45 represents a pinnacle of drilling technology, engineered for exceptional performance in demanding drilling operations. This robust drilling component features a male-female thread configuration with T45 specifications, ensuring secure connections and optimal power transmission during operation. The rod is manufactured from premium-grade steel, heat-treated to achieve the perfect balance of hardness and durability. With a precision-engineered thread profile, it enables quick and secure coupling while maintaining structural integrity under high torque conditions. The MF T45 design incorporates advanced features including enhanced thread protection, superior wear resistance, and optimized weight distribution for improved handling. This drill rod is particularly well-suited for applications in mining, quarrying, and construction projects where consistent performance and reliability are essential. The rod's design allows for efficient power transfer from the drilling machine to the bit, while its carefully calculated dimensions ensure optimal feed force and rotation speed capabilities. Its versatility makes it compatible with various drilling systems and suitable for both surface and underground operations.