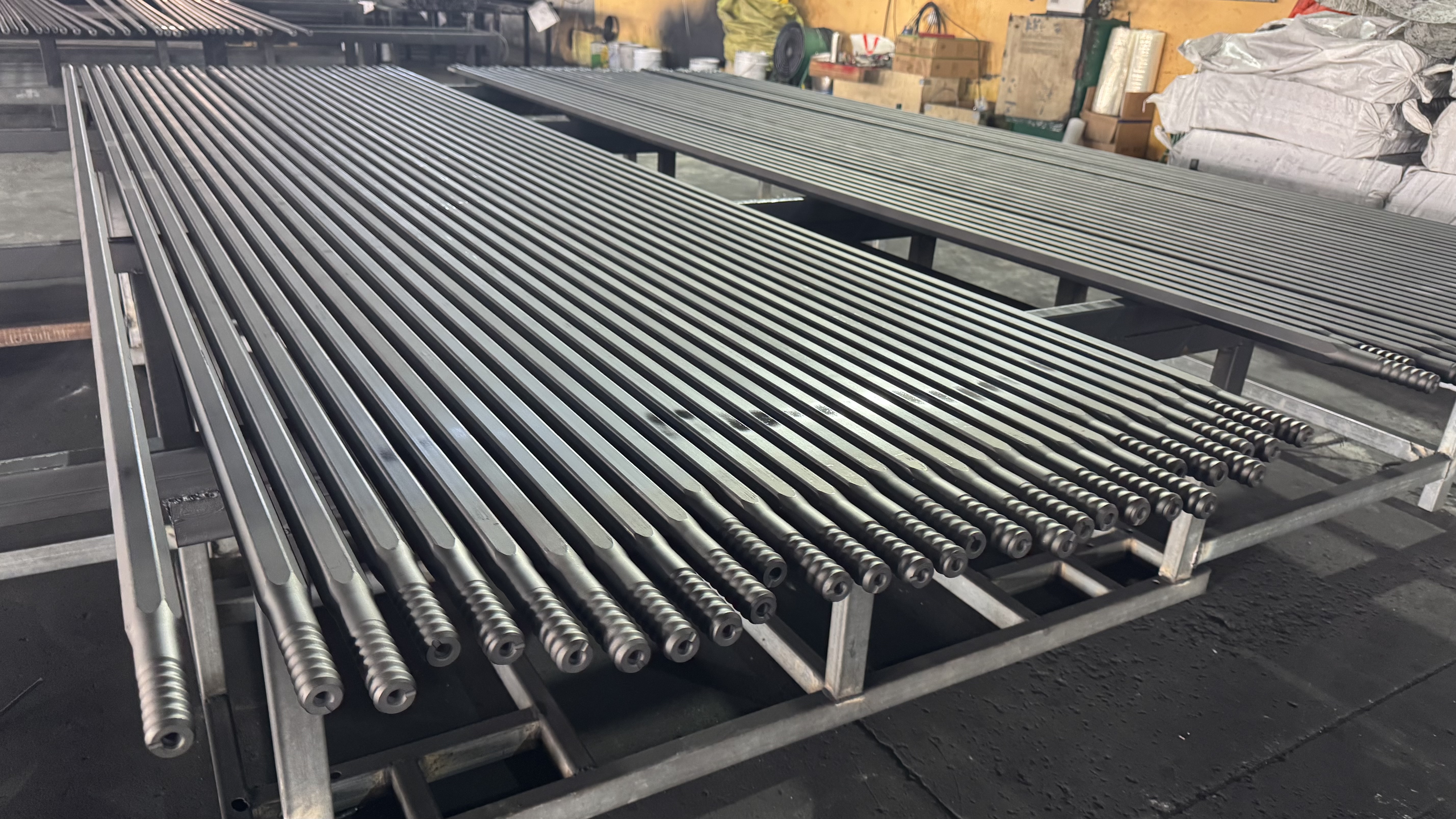

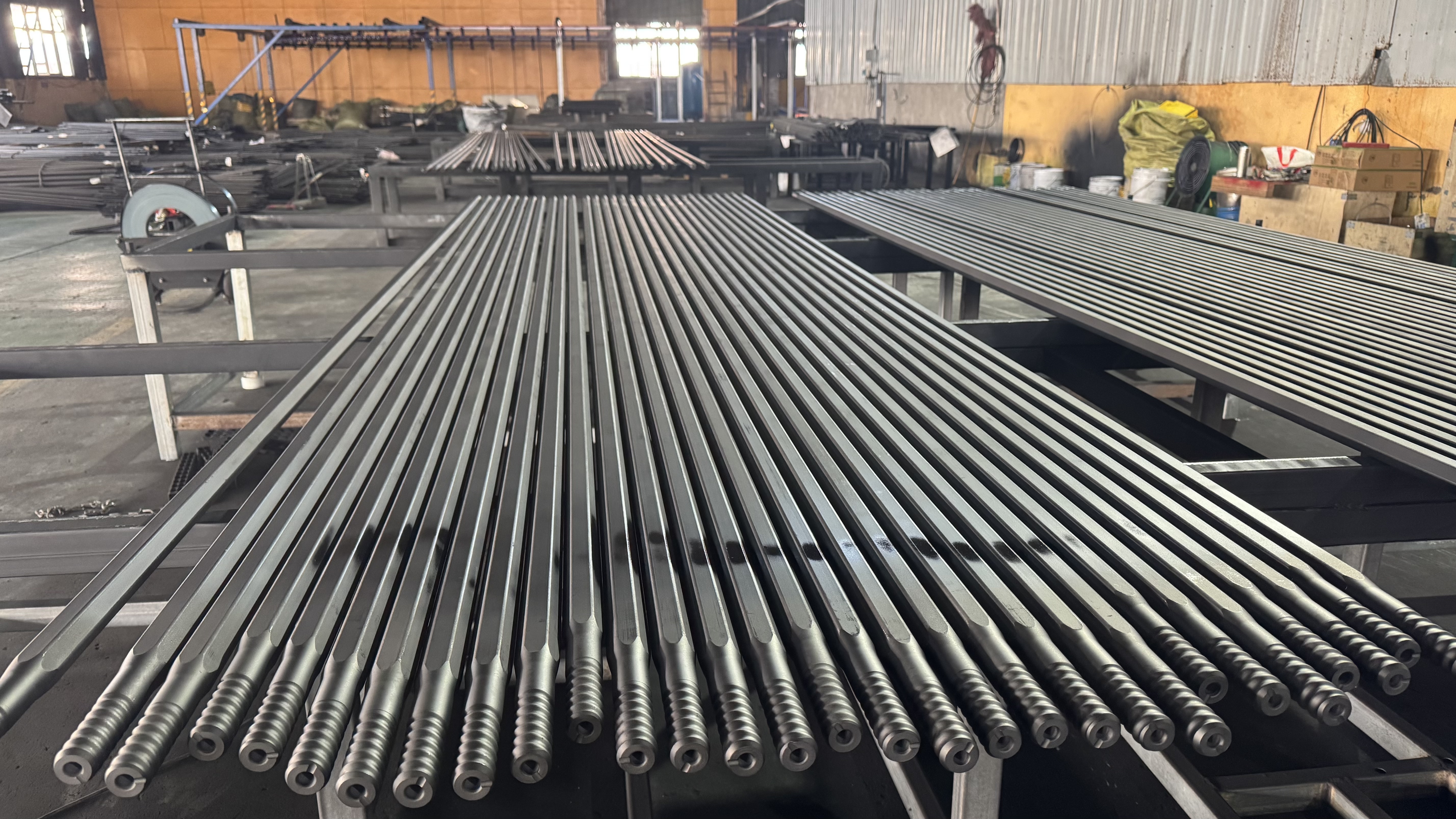

taper drill rod h22

The taper drill rod H22 represents a significant advancement in drilling technology, specifically engineered for superior performance in demanding drilling operations. This precision-engineered tool features a carefully designed tapered profile that optimizes drilling efficiency and reduces friction during operation. The H22 model is constructed from high-grade steel alloy, ensuring exceptional durability and resistance to wear under intense drilling conditions. The rod's unique taper design facilitates improved debris removal and enhanced drilling accuracy, making it particularly effective in deep-hole drilling applications. With its standardized H22 thread pattern, this drill rod ensures seamless compatibility with various drilling systems and equipment. The tool's balanced weight distribution and optimized length-to-diameter ratio contribute to reduced vibration during operation, resulting in more precise drilling outcomes. Its heat-treated surface provides additional protection against corrosion and extends the tool's operational lifespan. The taper drill rod H22 is widely utilized in mining operations, construction projects, and geological exploration, where reliable performance and consistent results are paramount.