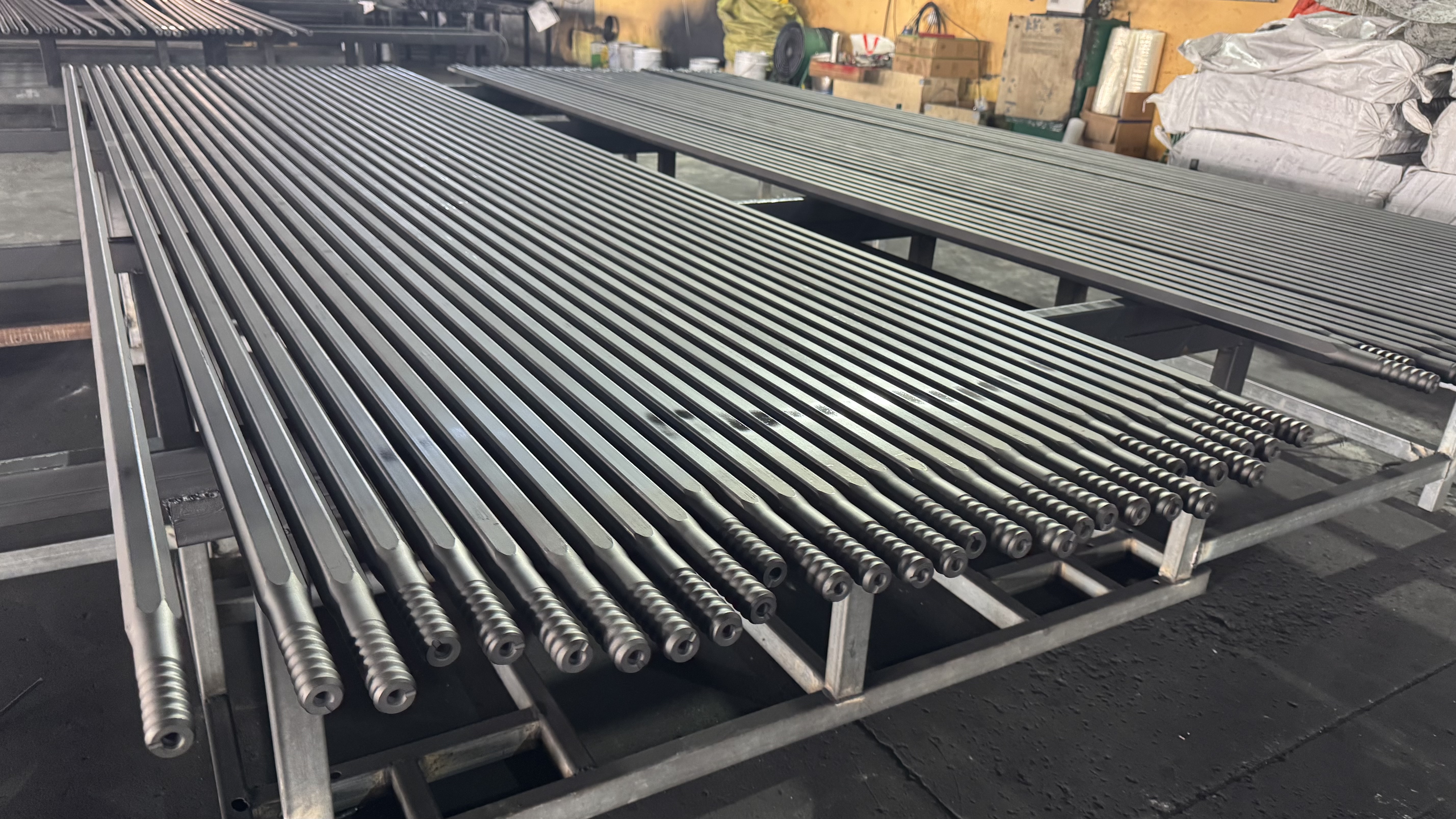

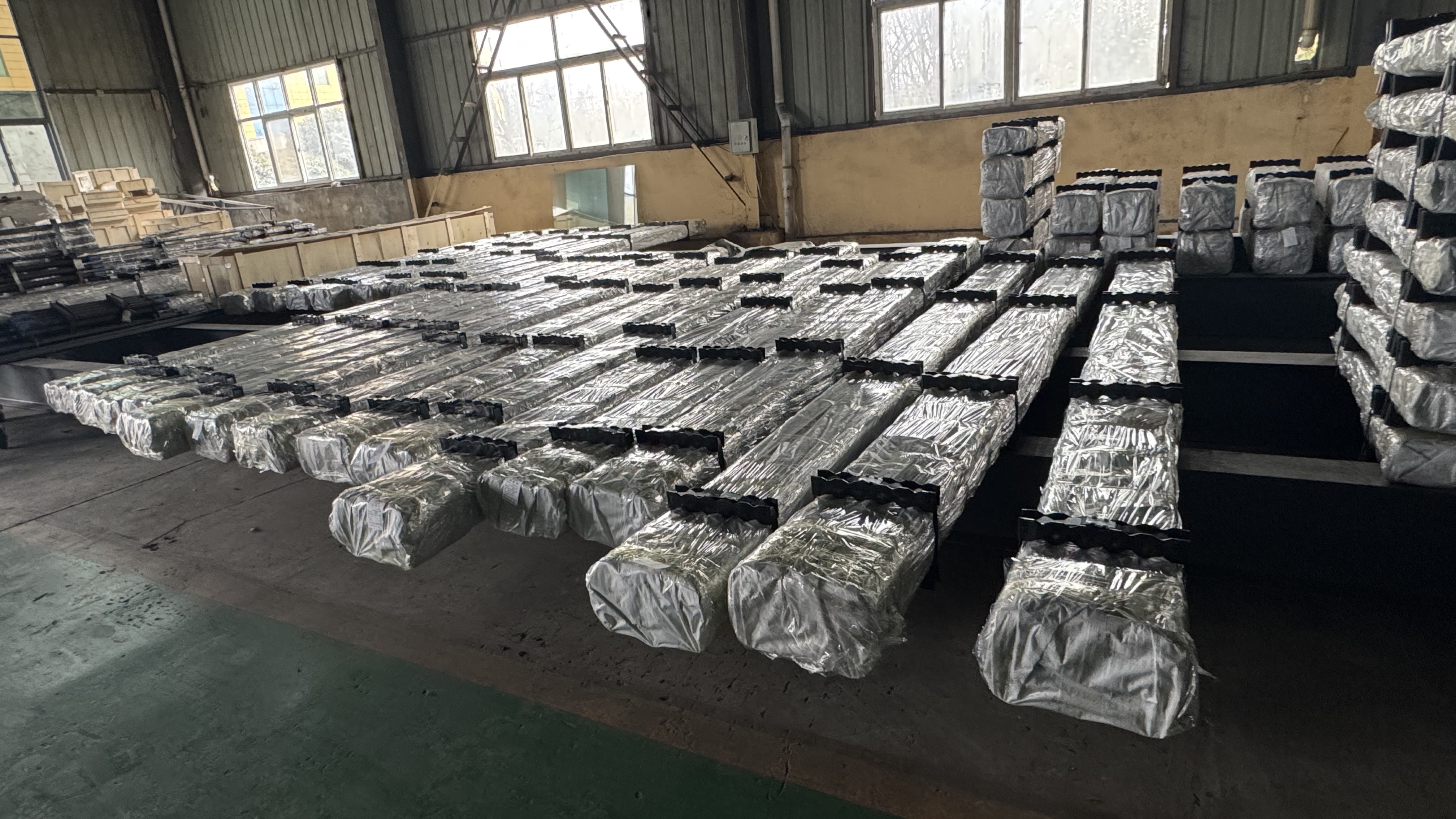

integral drill rod

The integral drill rod represents a significant advancement in drilling technology, combining durability and precision in a single, unified design. This essential drilling component features a one-piece construction that eliminates traditional connection points, resulting in enhanced structural integrity and improved performance during operation. The rod's seamless design incorporates high-grade steel materials, precision engineering, and advanced heat treatment processes to ensure optimal strength and wear resistance. Engineered for versatility, integral drill rods find applications across multiple industries, including mining, construction, and geological exploration. The innovative design allows for superior torque transmission and reduced vibration during drilling operations, leading to more accurate hole placement and consistent drilling results. These rods are specifically designed to withstand high-pressure conditions and extreme temperatures while maintaining their structural integrity. The absence of threaded connections minimizes the risk of thread wear and failure, a common issue with conventional drill rods. Additionally, the integral design facilitates better fluid flow dynamics, ensuring efficient cooling and debris removal during drilling operations.