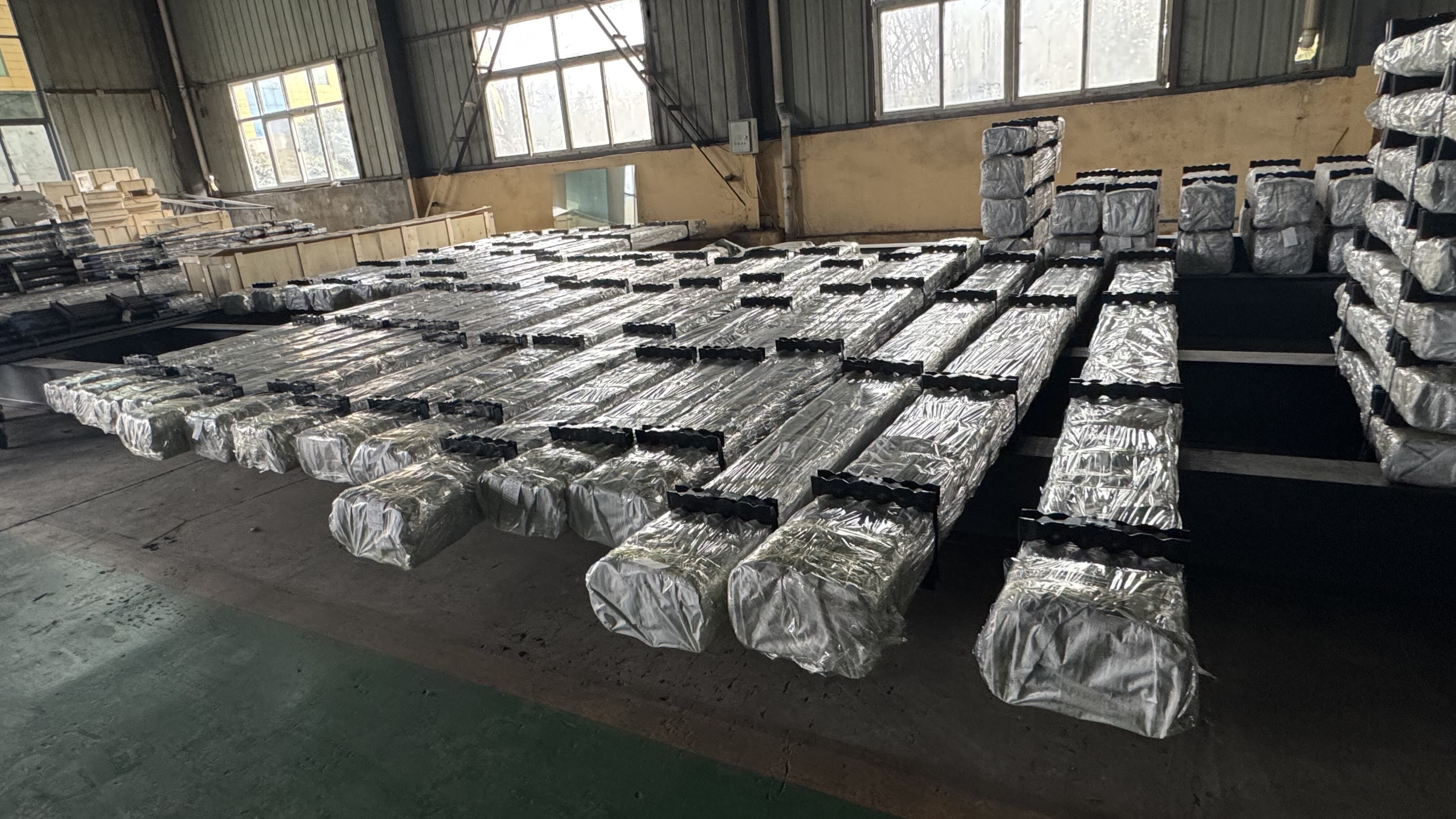

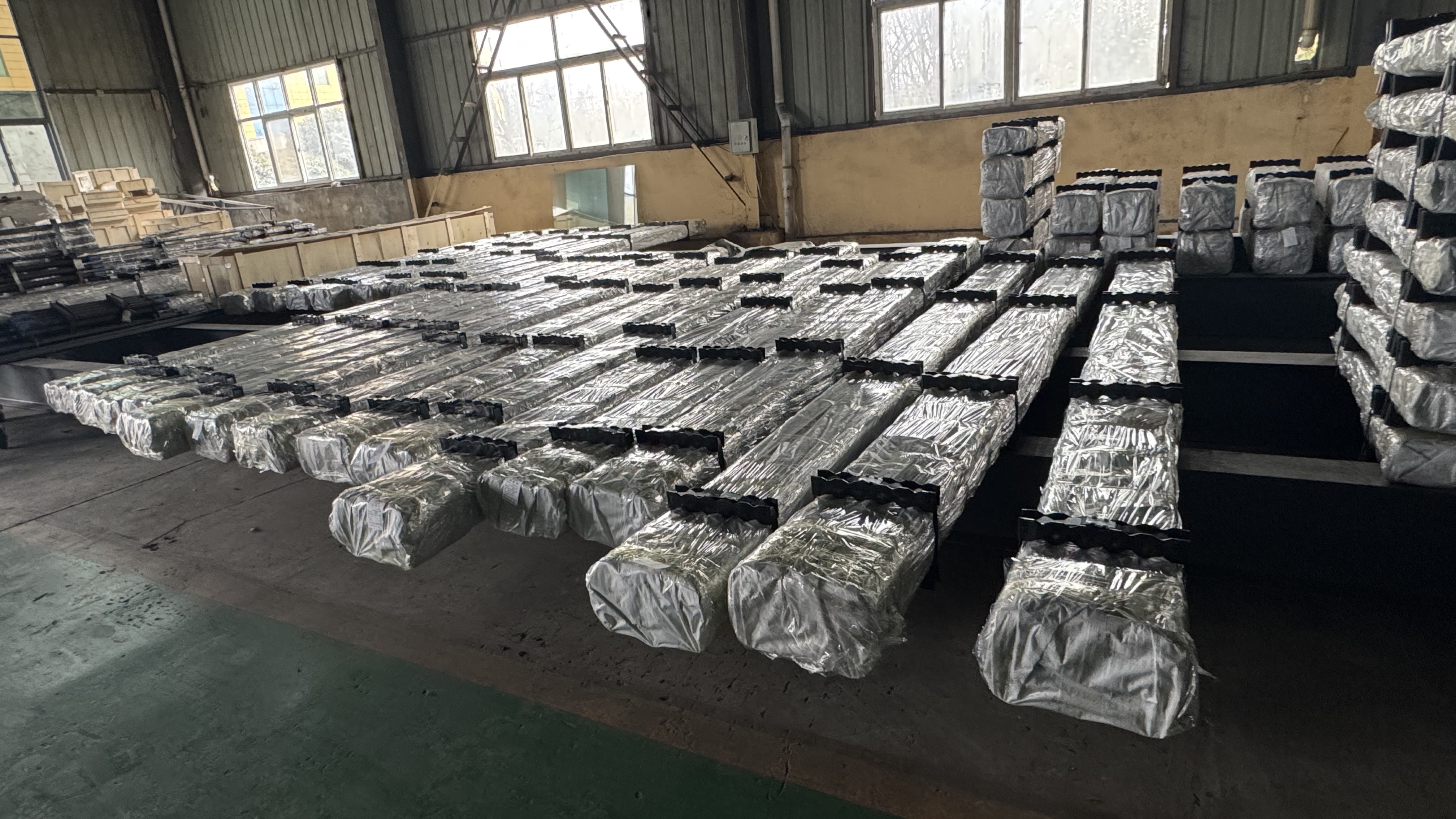

tapered drill rod

A tapered drill rod is a specialized drilling tool designed with a gradually decreasing diameter from top to bottom, engineered for superior performance in various drilling applications. This precision-engineered tool combines advanced metallurgy with innovative design principles to deliver exceptional drilling efficiency and reliability. The tapered construction allows for improved weight distribution and enhanced stress management throughout the rod's length, resulting in better control during drilling operations. The design significantly reduces vibration during operation, which not only extends the tool's lifespan but also ensures more accurate hole placement and consistent drilling results. These rods are manufactured using high-grade steel alloys, carefully heat-treated to achieve optimal hardness and durability. The tapered profile facilitates smoother drilling operations by providing better chip evacuation and reducing friction between the rod and the hole wall. This design also allows for increased depth capability while maintaining structural integrity, making it particularly valuable in deep-hole drilling applications. The versatility of tapered drill rods makes them suitable for various industries, including mining, construction, and geological exploration, where precision and reliability are paramount.