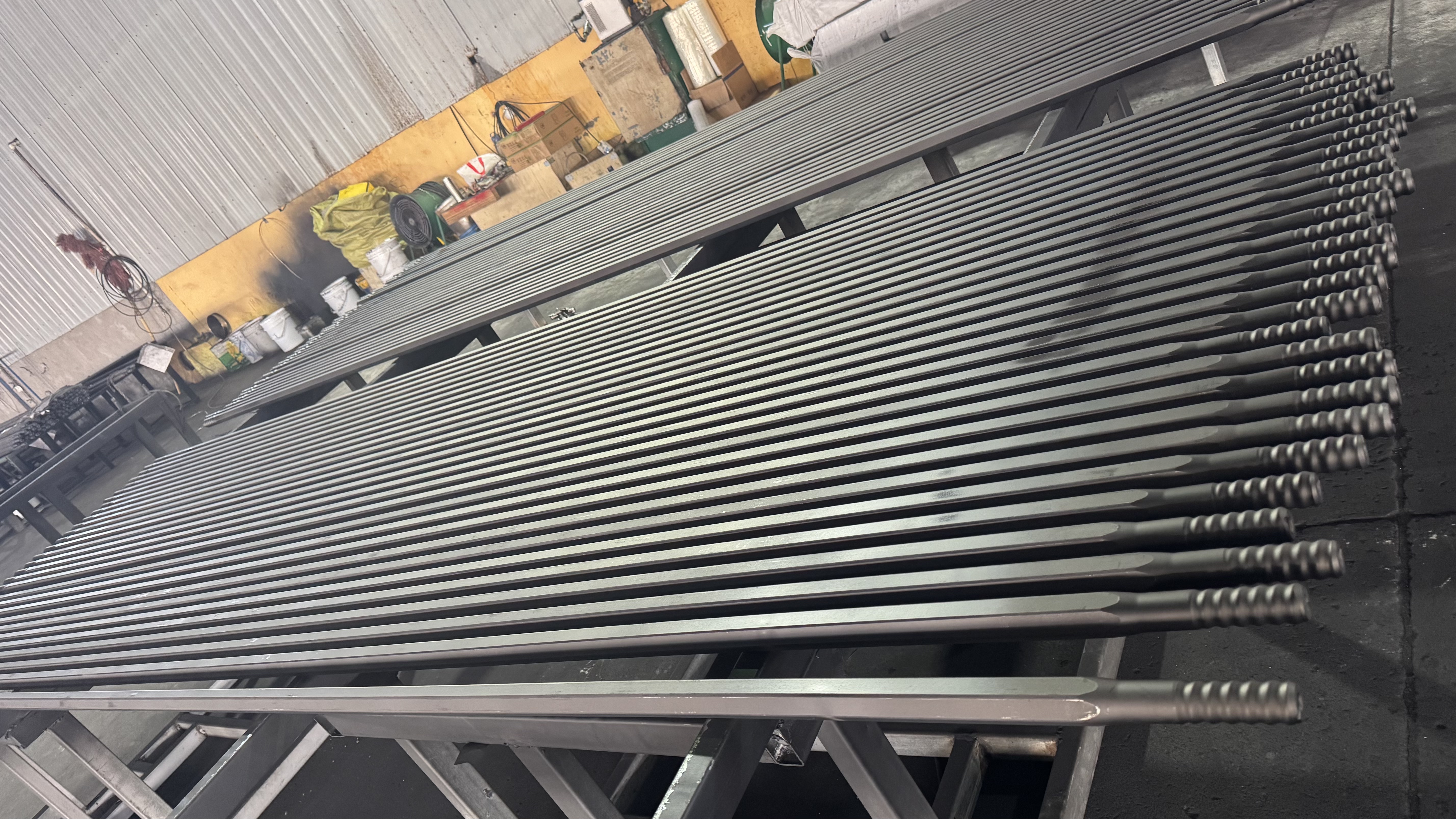

drill rod mf t51

The drill rod MF T51 represents a significant advancement in drilling technology, offering exceptional performance and reliability for various drilling applications. This professional-grade drilling component features a robust male-female thread connection system, specifically designed for T51 thread specifications. The rod is manufactured from high-grade alloy steel, ensuring superior strength and durability under demanding conditions. With its precision-engineered design, the MF T51 delivers optimal energy transfer during drilling operations, maximizing efficiency and reducing power loss. The rod's thread profile is carefully crafted to maintain tight connections while allowing for quick coupling and decoupling in the field. Its balanced weight distribution and structural integrity help minimize vibration during operation, leading to more accurate drilling results and extended service life. The MF T51 is particularly well-suited for applications in mining, quarrying, and construction projects, where consistent performance and reliability are essential. The rod's surface treatment provides excellent resistance to wear and corrosion, ensuring sustained performance even in challenging environmental conditions.