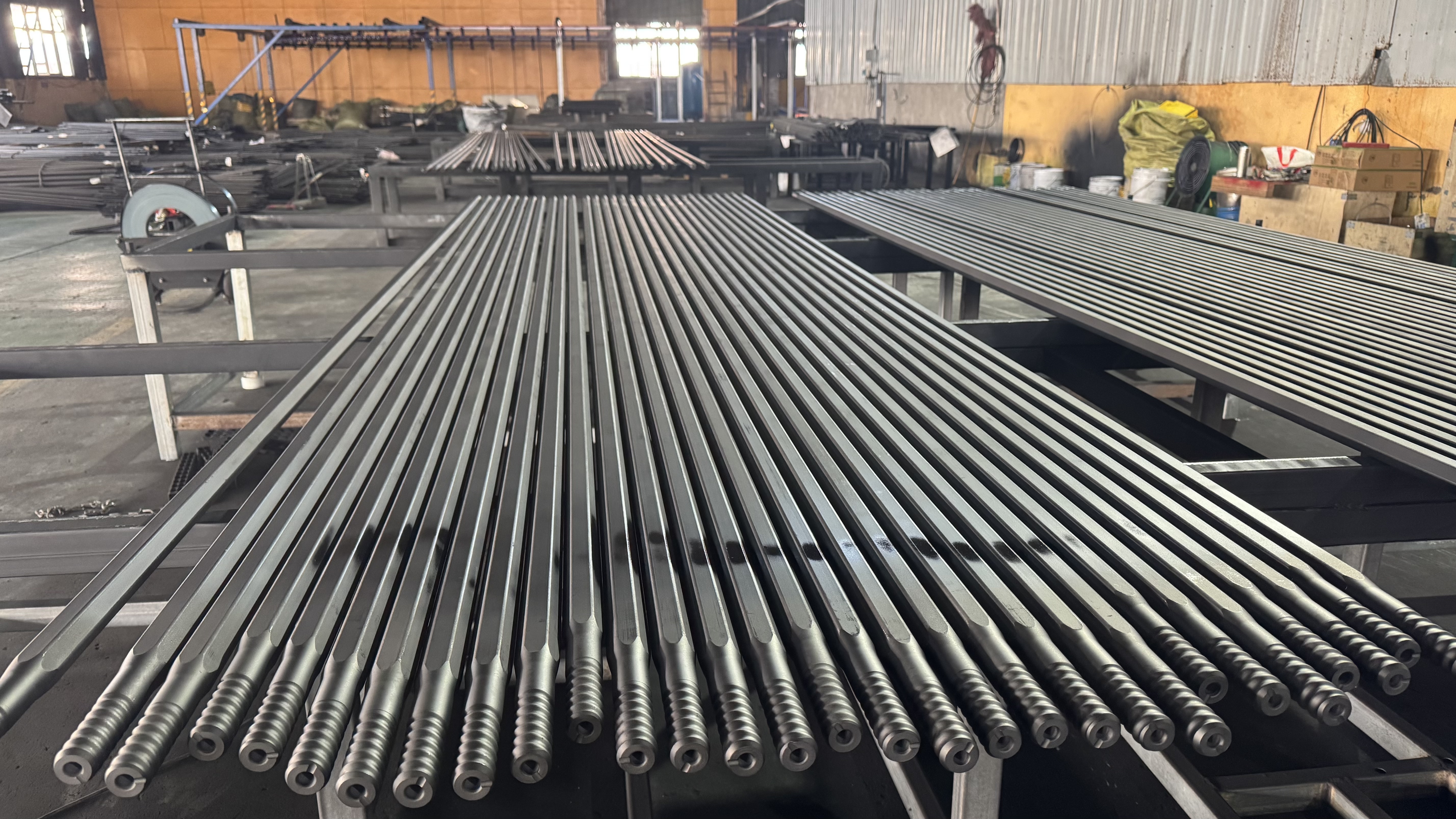

down hole drilling equipment

Down hole drilling equipment represents a crucial component in modern drilling operations, comprising sophisticated tools and machinery designed to perform efficient and precise drilling activities beneath the Earth's surface. This advanced equipment includes various essential components such as drill bits, drill strings, measurement while drilling (MWD) tools, and logging while drilling (LWD) systems. The primary function of down hole drilling equipment is to create boreholes for resource extraction, exploration, and construction purposes. These tools are engineered to withstand extreme conditions, including high pressures, temperatures, and corrosive environments. The technology incorporates state-of-the-art sensors and control systems that provide real-time data about drilling parameters, formation characteristics, and equipment performance. Modern down hole drilling equipment features advanced directional drilling capabilities, allowing operators to navigate complex well paths and reach targeted formations with unprecedented accuracy. The applications span across multiple industries, including oil and gas exploration, geothermal energy development, mining, and water well drilling. The equipment's versatility enables it to operate in various geological formations, from soft sedimentary rocks to hard crystalline formations, making it an indispensable tool in drilling operations worldwide.