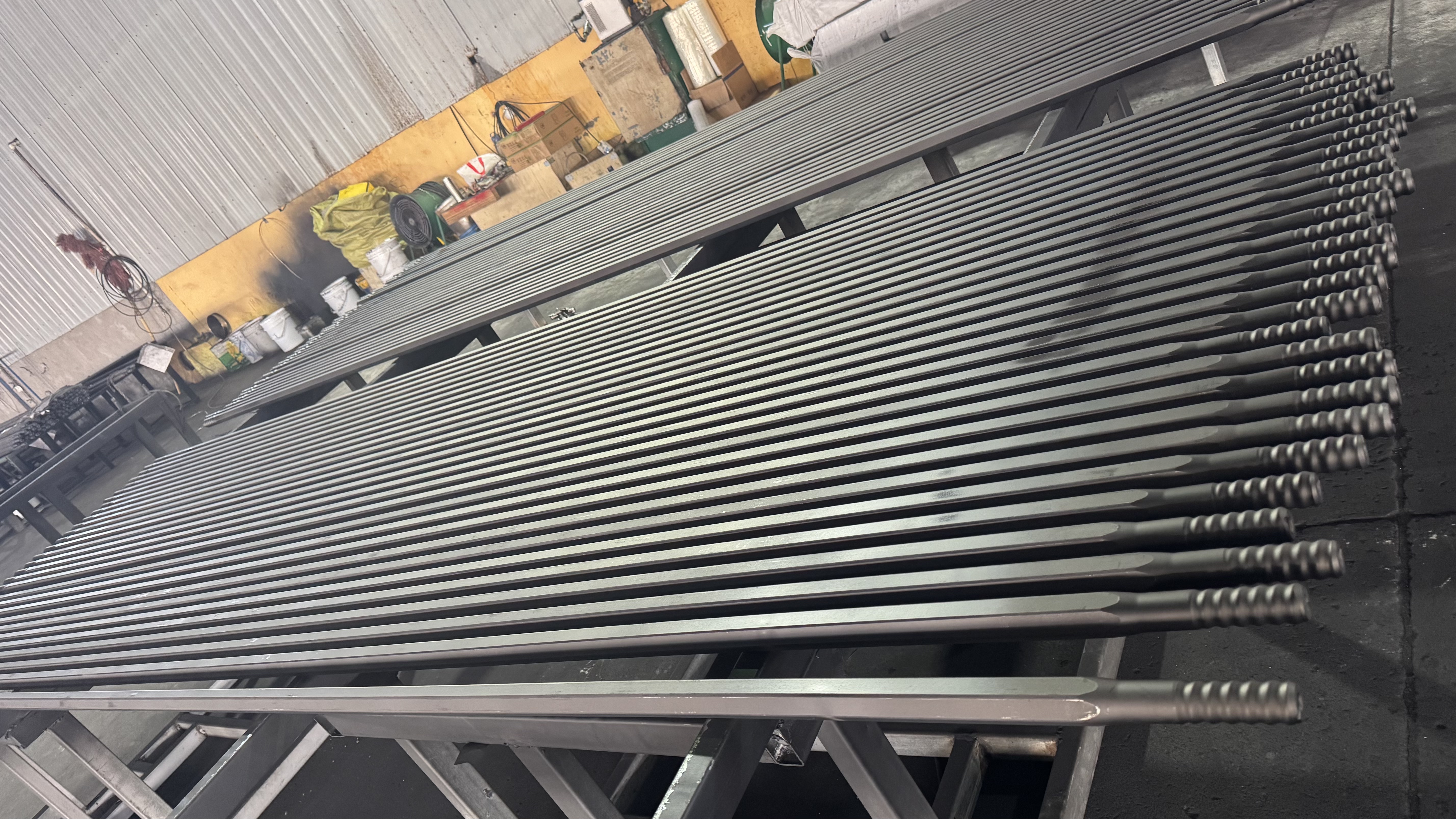

down the hole drilling

Down the hole drilling is a sophisticated drilling technique that revolutionizes the way we approach deep hole drilling operations. This method utilizes a unique hammer drilling system where the percussion mechanism is located directly behind the drill bit at the bottom of the hole. The system consists of three main components: a drill bit, a hammer mechanism, and drill pipes. As compressed air is forced down through the drill string, it activates the hammer mechanism, creating rapid and powerful impacts directly on the drill bit. This direct transfer of energy results in exceptional drilling efficiency, particularly in hard rock formations. The technology excels in applications ranging from water well drilling and geothermal exploration to mining operations and construction projects. What sets this method apart is its ability to maintain straight and accurate holes, even at significant depths, due to the hammer's placement near the cutting face. The system also provides superior hole cleaning capabilities through the continuous flow of compressed air, which effectively removes cuttings and debris from the hole. Modern down the hole drilling systems incorporate advanced features such as automated rod handling systems, real-time monitoring capabilities, and adjustable impact energy control, making them highly versatile and efficient for various drilling applications.