dth hammer breakout bench

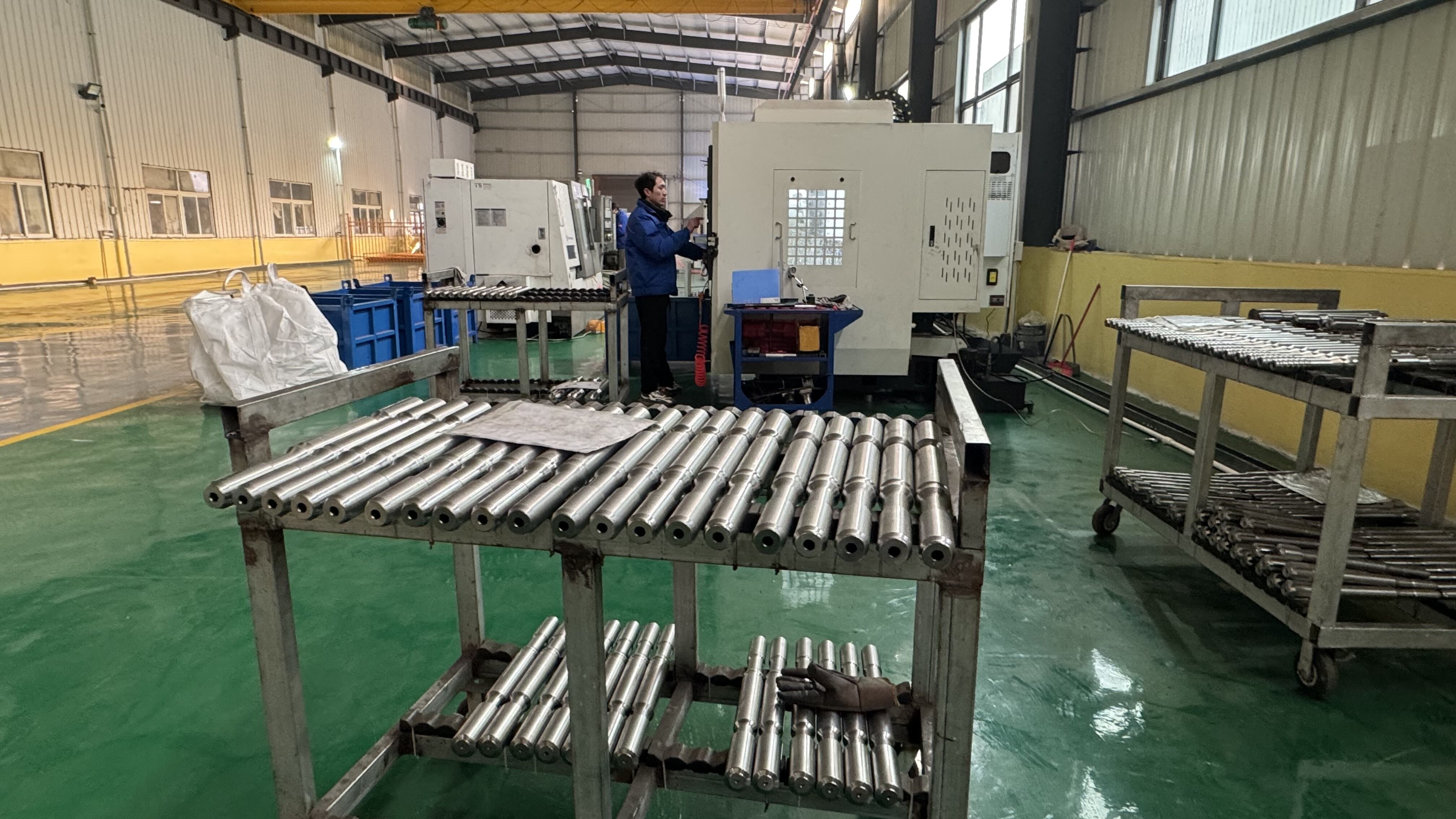

The DTH hammer breakout bench is an essential piece of equipment designed specifically for the maintenance and servicing of Down-the-Hole (DTH) hammers used in drilling operations. This sophisticated workstation combines robust construction with precision engineering to provide a safe and efficient platform for disassembling and reassembling DTH hammers. The bench features a heavy-duty steel frame that ensures stability during operation, along with adjustable clamping mechanisms that can accommodate various hammer sizes from different manufacturers. The unit includes specialized holding fixtures and torque-controlled tools that prevent damage to hammer components during maintenance procedures. Advanced safety features include lockable clamps, non-slip surfaces, and ergonomic working heights that reduce operator strain. The bench's modular design incorporates dedicated storage areas for tools and spare parts, while its corrosion-resistant coating ensures longevity in challenging workshop environments. This equipment significantly reduces maintenance time by providing a structured workspace with all necessary tools within reach, enabling technicians to perform repairs and maintenance efficiently. The bench's versatile design allows for 360-degree access to the hammer components, facilitating thorough inspection and precise assembly.