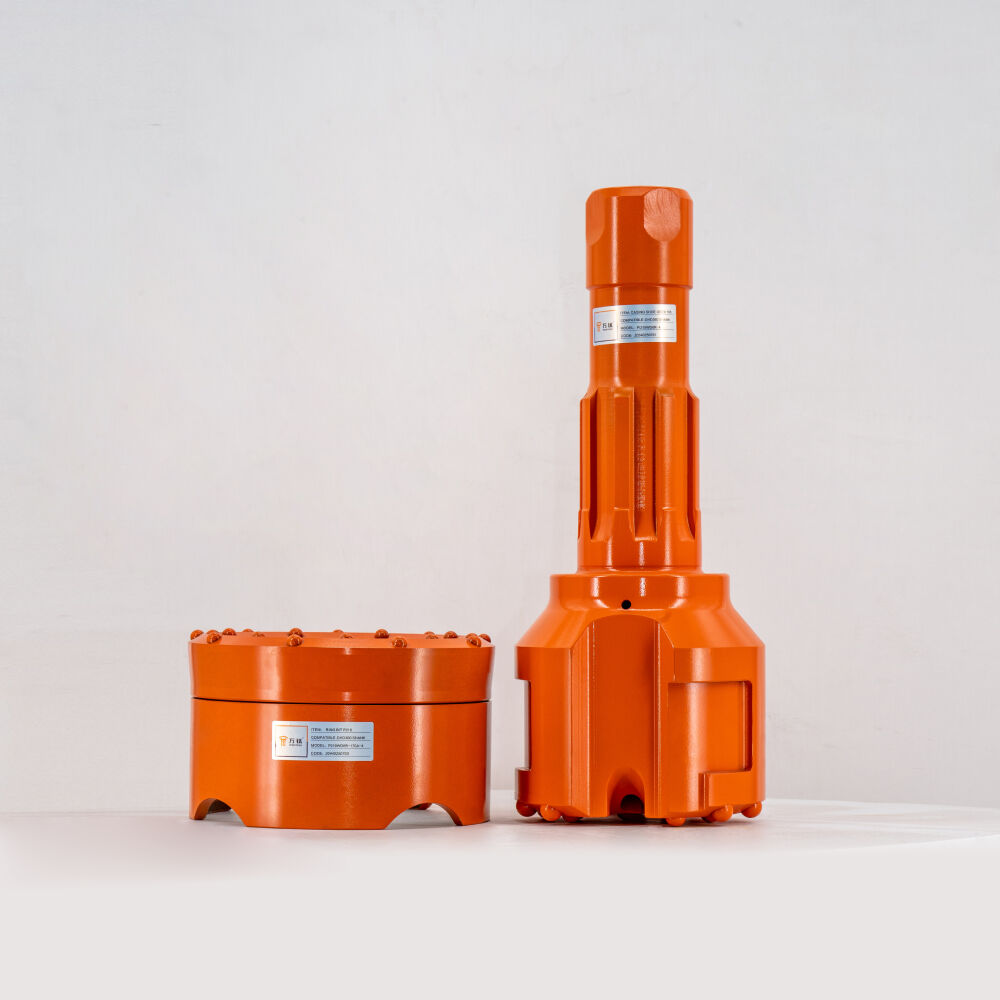

dth bits manufacturers

DTH bits manufacturers are specialized companies that produce Down-the-Hole drilling bits, essential tools in the mining, construction, and exploration industries. These manufacturers employ advanced engineering processes and high-grade materials to create durable, efficient drilling solutions. Their products are designed to withstand extreme pressure, temperature, and abrasive conditions while maintaining optimal performance. Modern DTH bits manufacturers integrate cutting-edge technology in their production processes, including computer-aided design (CAD) systems and precision machining equipment, ensuring consistent quality and accuracy in every product. They typically offer a comprehensive range of bits suitable for various ground conditions, from soft sedimentary rocks to extremely hard crystalline formations. These manufacturers focus on developing innovative designs that enhance drilling efficiency, reduce operational costs, and extend product lifespan. Their manufacturing facilities are equipped with state-of-the-art quality control systems, ensuring each bit meets strict industry standards and specifications. Many manufacturers also provide customization options to meet specific project requirements, backed by technical support and expertise in bit selection and application.