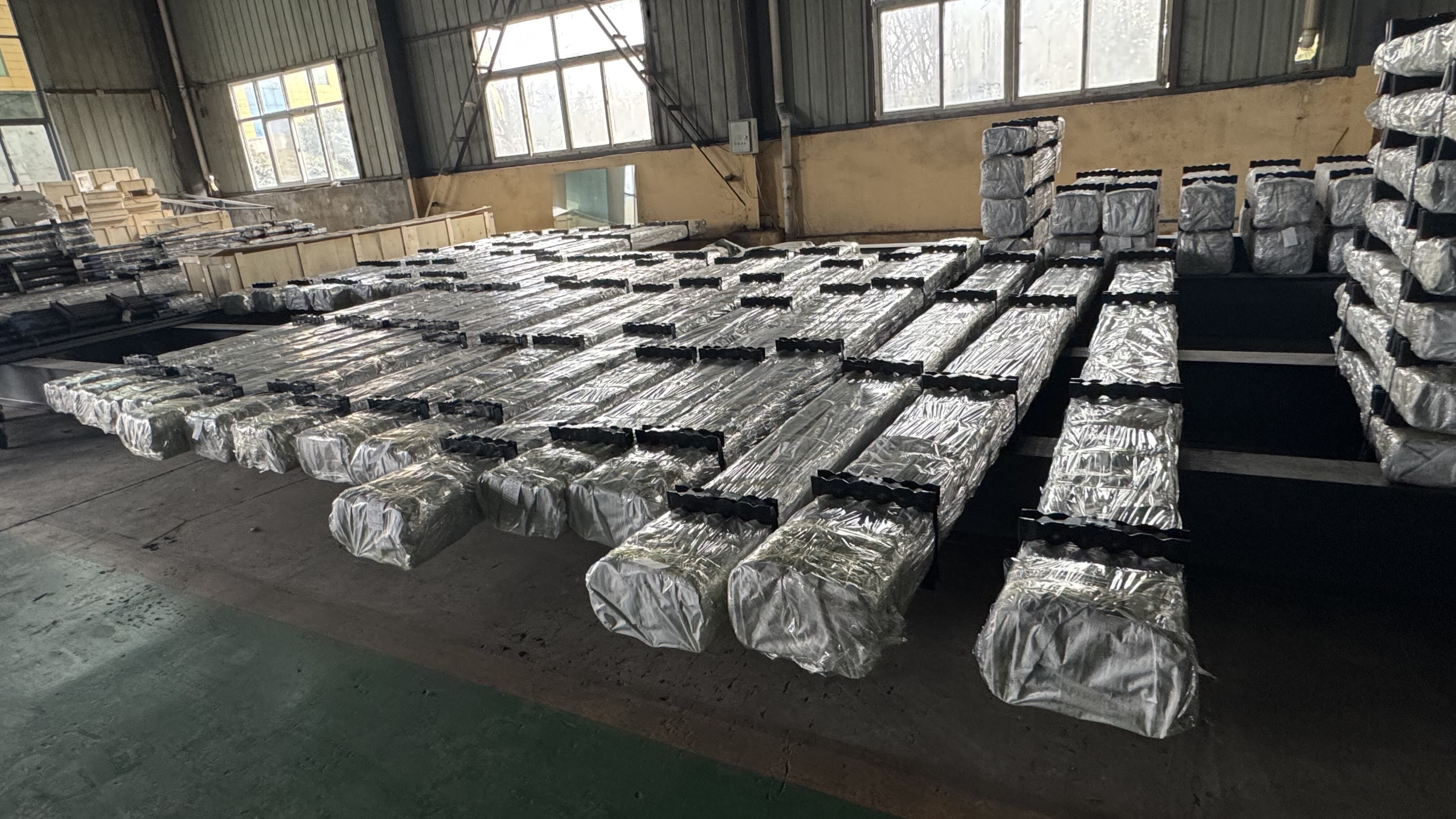

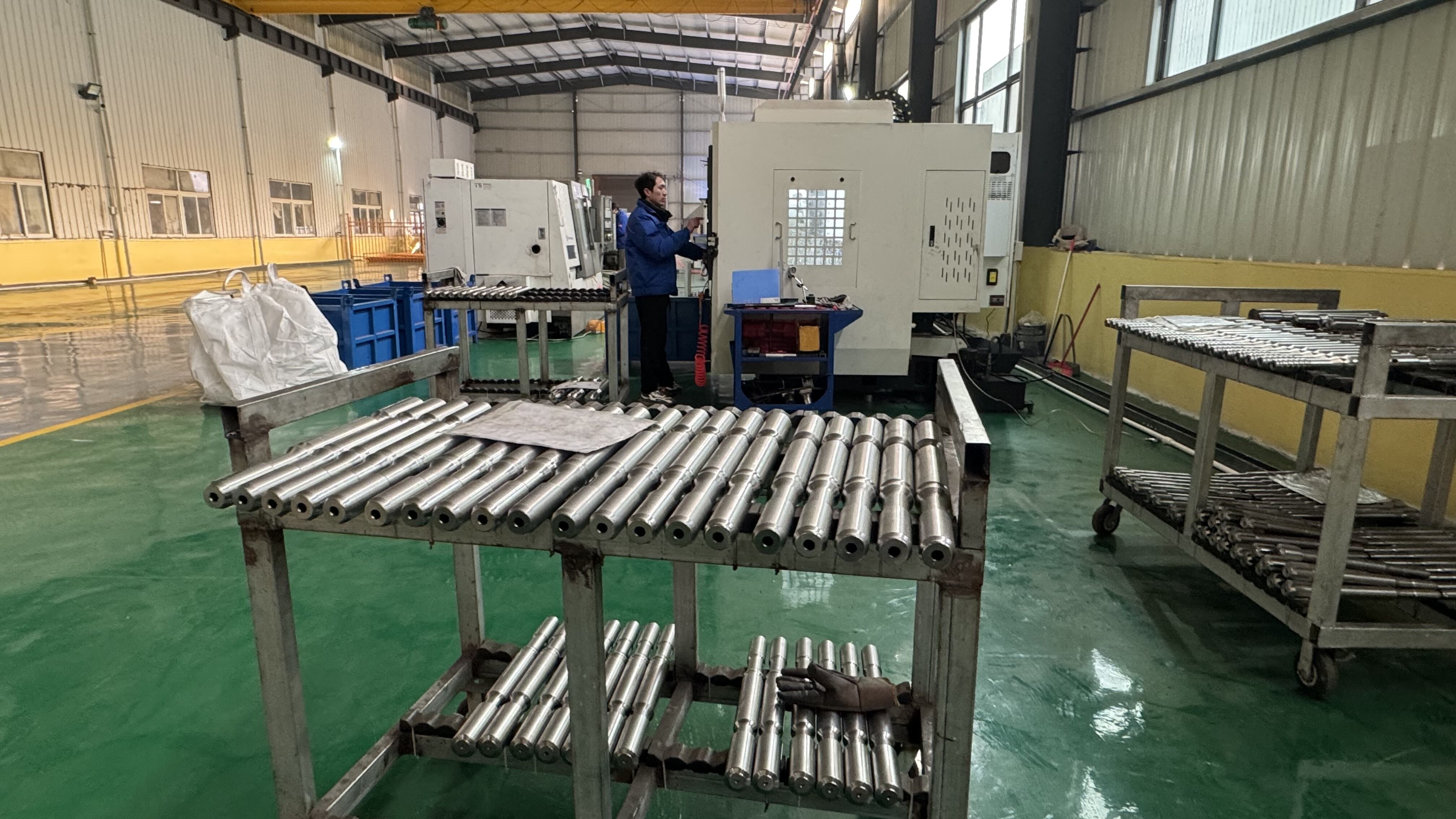

down the hole drilling tools

Down the hole (DTH) drilling tools represent a sophisticated advancement in modern drilling technology, specifically engineered for high-performance drilling operations in various ground conditions. These tools consist of a hammer mechanism that operates at the bottom of the borehole, directly behind the drill bit, delivering powerful percussive blows while rotating. The system comprises several key components including the hammer, drill bit, drill tubes, and a power source that supplies compressed air or hydraulic pressure. This configuration enables exceptional drilling efficiency by minimizing energy loss through the drill string, as the impact force is generated directly above the bit. DTH tools excel in applications requiring deep holes in hard rock formations, achieving superior penetration rates compared to conventional rotary drilling methods. The technology incorporates advanced engineering features such as optimized impact frequency, enhanced air flow management, and wear-resistant materials that significantly extend tool life. These tools are particularly valuable in mining, quarrying, water well drilling, and construction projects, offering versatility across different geological formations. Modern DTH tools also feature sophisticated dust suppression systems and noise reduction technologies, addressing environmental and safety concerns while maintaining optimal performance levels.