dth hammer bits manufacturers

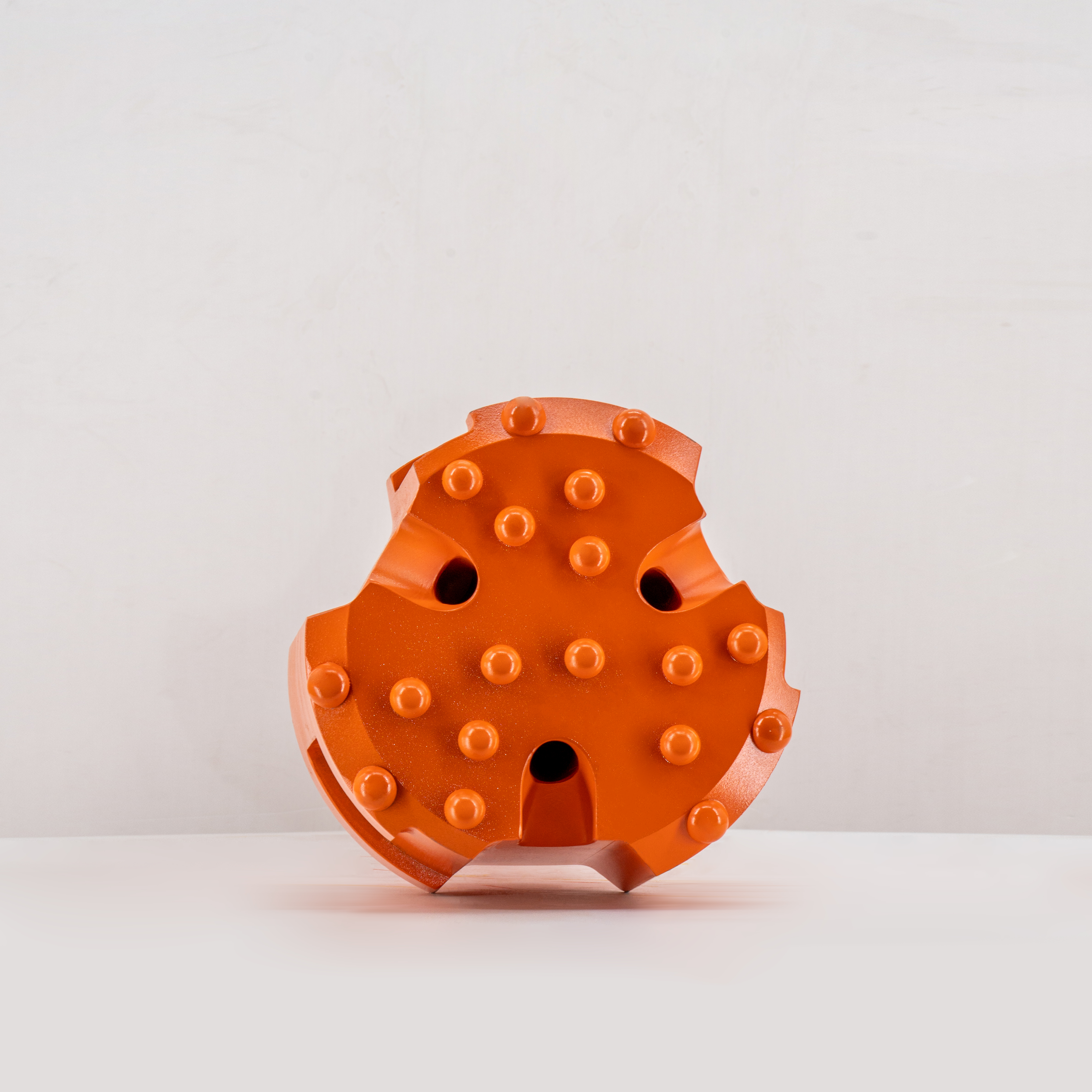

DTH hammer bits manufacturers represent a crucial segment in the mining and construction industry, specializing in the production of high-performance down-the-hole drilling equipment. These manufacturers employ advanced engineering processes and cutting-edge technology to create robust drilling tools that excel in challenging geological conditions. Their product lines typically include various bit designs optimized for different rock formations, ranging from soft to extremely hard materials. These manufacturers integrate premium-grade materials, such as tungsten carbide and high-strength steel alloys, to ensure maximum durability and drilling efficiency. The manufacturing process involves sophisticated computer-aided design systems, precise machining operations, and rigorous quality control measures. Modern DTH hammer bits manufacturers also focus on innovative features like advanced button placement patterns, optimized flushing channels, and wear-resistant coatings to enhance drilling performance and extend bit life. They provide customization options to meet specific project requirements, offering various sizes, designs, and specifications to suit different drilling applications, from water well drilling to mining operations and construction projects.