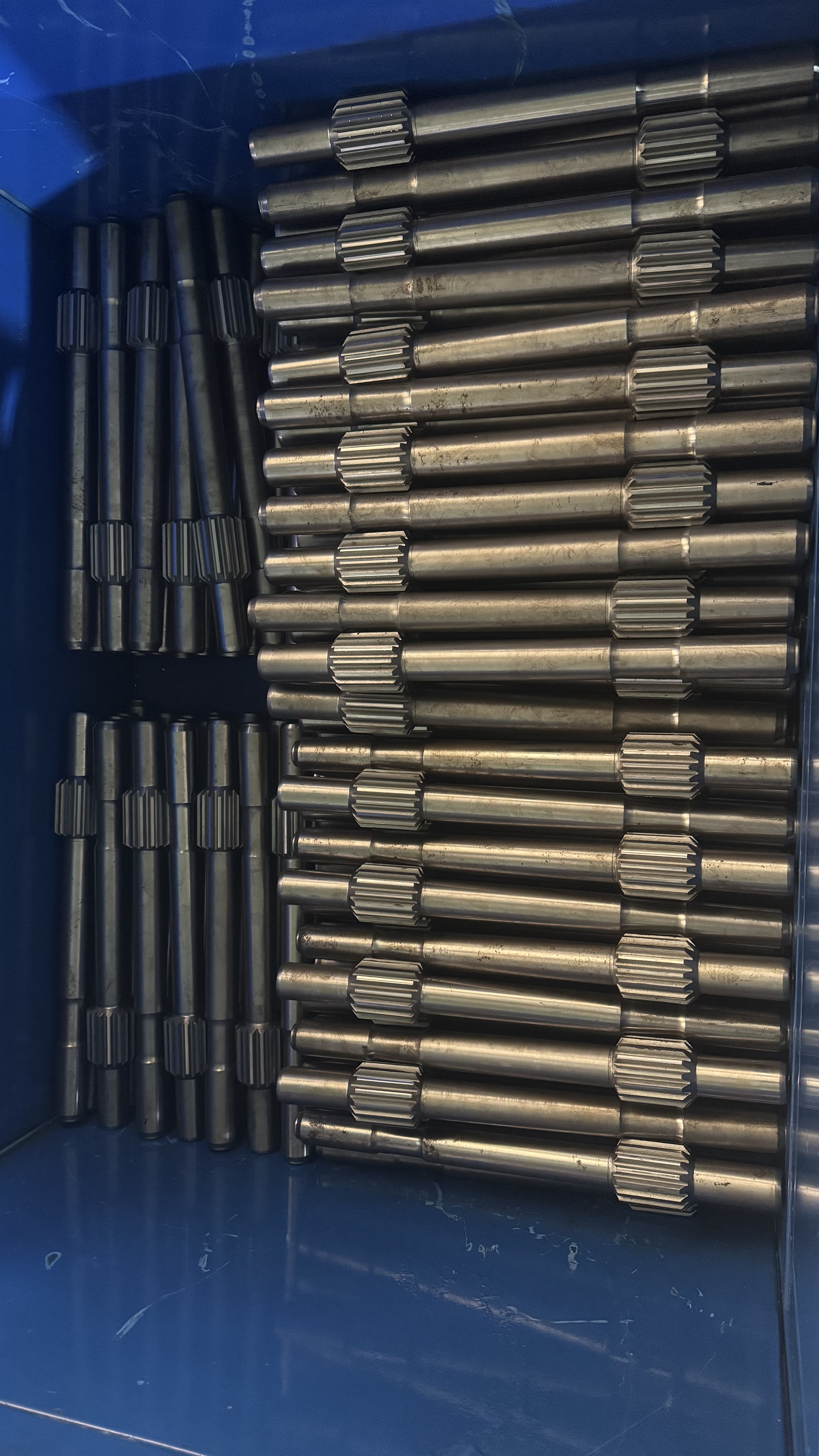

dth hammer

The DTH hammer, or Down-the-Hole hammer, represents a revolutionary advancement in drilling technology, combining robust engineering with precision performance. This essential drilling tool operates through a percussion mechanism that delivers powerful impact force directly to the drill bit at the bottom of the borehole. The system comprises a piston that moves rapidly within the hammer body, striking the drill bit to generate the necessary force for breaking through rock formations. Operating on compressed air, the DTH hammer utilizes this power source to drive both the hammering action and the rotation of the drill bit, ensuring optimal drilling efficiency. The tool's design incorporates sophisticated air flow channels that not only power the hammer mechanism but also facilitate the removal of drill cuttings from the hole. Modern DTH hammers feature advanced materials and precision engineering that contribute to extended service life and improved drilling rates. These tools are particularly effective in hard rock formations and deep hole applications, where traditional rotary drilling methods may prove less efficient. The versatility of DTH hammers makes them invaluable in various applications, including water well drilling, mining exploration, construction, and geotechnical investigations. Their ability to maintain straight holes and achieve faster penetration rates has established them as a preferred choice in the drilling industry.