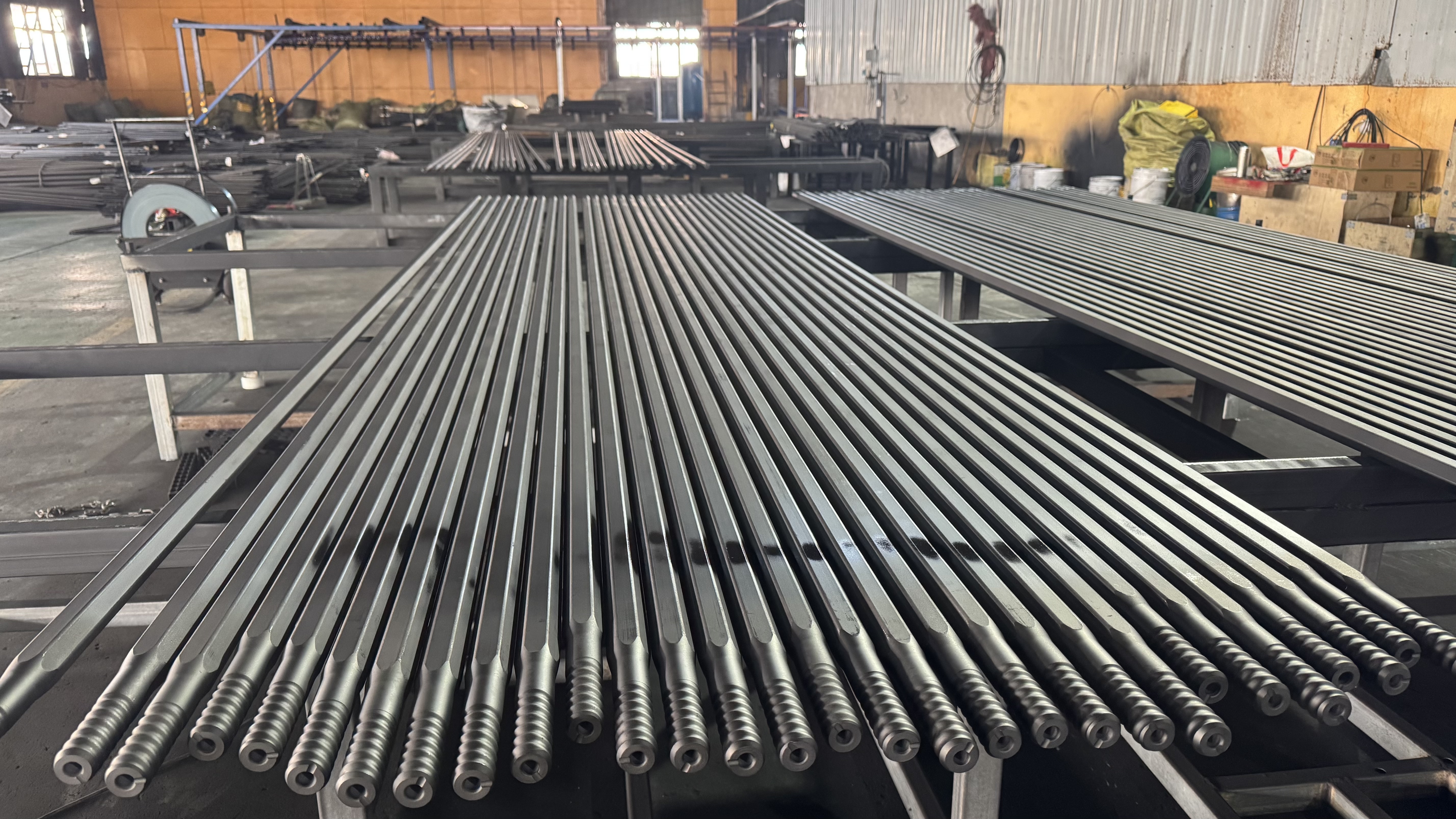

tricone rock bit

The tricone rock bit represents a groundbreaking advancement in drilling technology, featuring three rotating cones equipped with specially designed teeth or inserts. This sophisticated drilling tool has revolutionized the mining, oil, and gas industries through its exceptional ability to crush and pulverize hard rock formations efficiently. The unique design incorporates three conical cutters that rotate independently on sealed bearings, enabling the bit to maintain consistent contact with the rock surface while drilling. Each cone is strategically positioned at precise angles to maximize cutting efficiency and ensure optimal penetration rates. The tricone rock bit's robust construction typically features hardened steel or tungsten carbide inserts, providing superior wear resistance and extended operational life in demanding conditions. Its versatility allows for effective drilling in various formation types, from soft to extremely hard rock layers. The bit's sophisticated hydraulic design includes strategically placed nozzles that facilitate efficient cleaning and cooling during operation, preventing bit balling and ensuring consistent performance. Modern tricone bits often incorporate advanced features such as premium sealing systems, optimized cutting structures, and enhanced bearing packages, making them indispensable tools in modern drilling operations. The technology continues to evolve with improvements in materials science and engineering, resulting in better performance metrics and increased durability in challenging drilling environments.