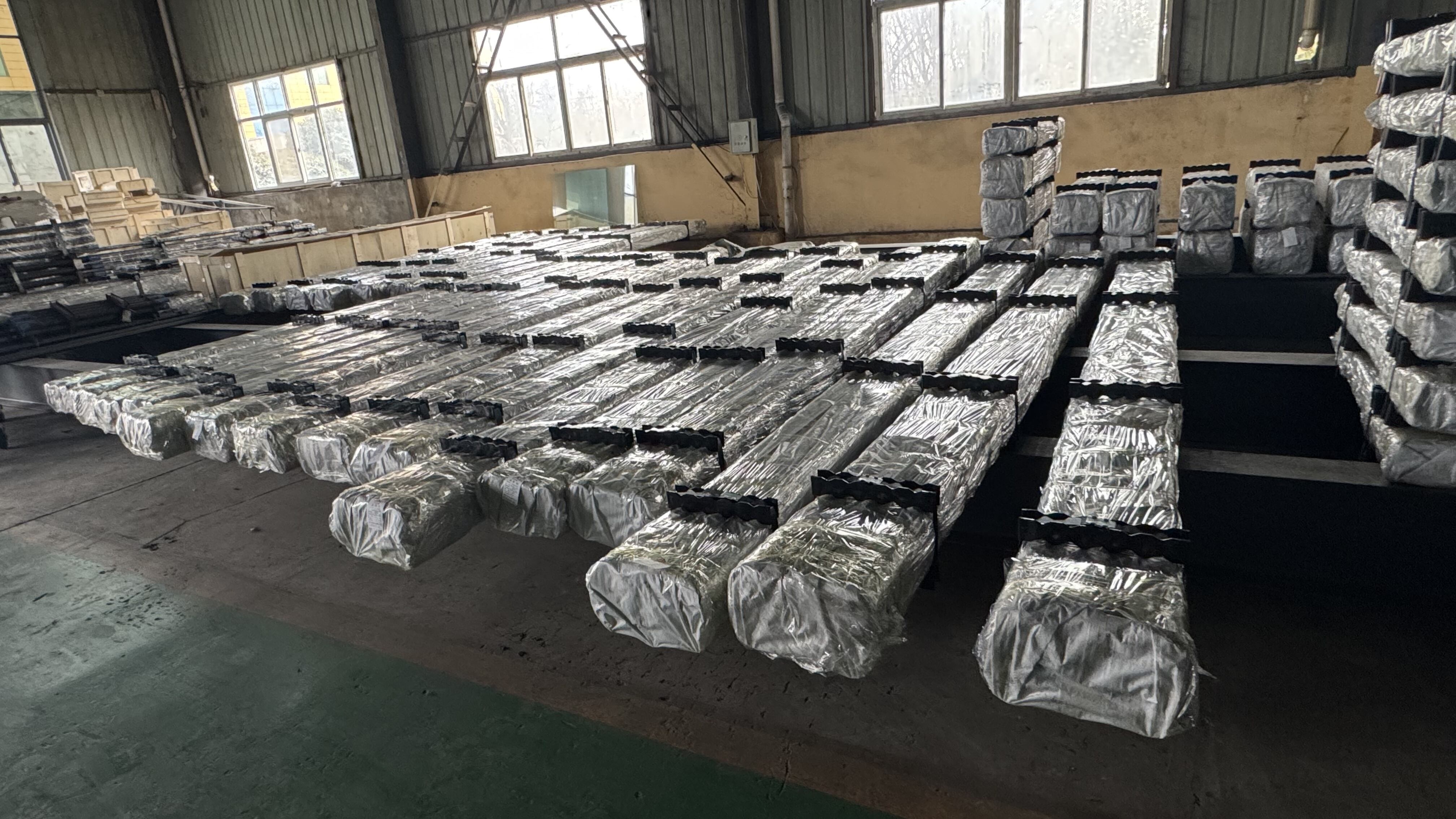

tricone drill bit for sale

The tricone drill bit represents a pinnacle of drilling technology, engineered specifically for demanding drilling operations across various geological formations. This robust tool features three rotating cones equipped with strategically positioned tungsten carbide inserts or steel teeth, designed to efficiently crush and pulverize rock formations. Each cone rotates independently on sealed bearing systems, ensuring optimal cutting action and extended operational life. The bit's sophisticated hydraulic design incorporates carefully positioned nozzles that deliver drilling fluid to cool the cutting structure and efficiently remove cuttings from the drilling zone. Available in various sizes ranging from 3.75 to 26 inches in diameter, these bits are engineered to meet diverse drilling requirements. The tricone design enables superior penetration rates in medium to hard formations while maintaining excellent directional control. Advanced metallurgical compositions in the bit body and cutting structures provide exceptional wear resistance and durability under extreme conditions. The bearing systems are sealed and lubricated to protect against abrasive drilling fluids and cuttings, significantly extending the bit's service life.