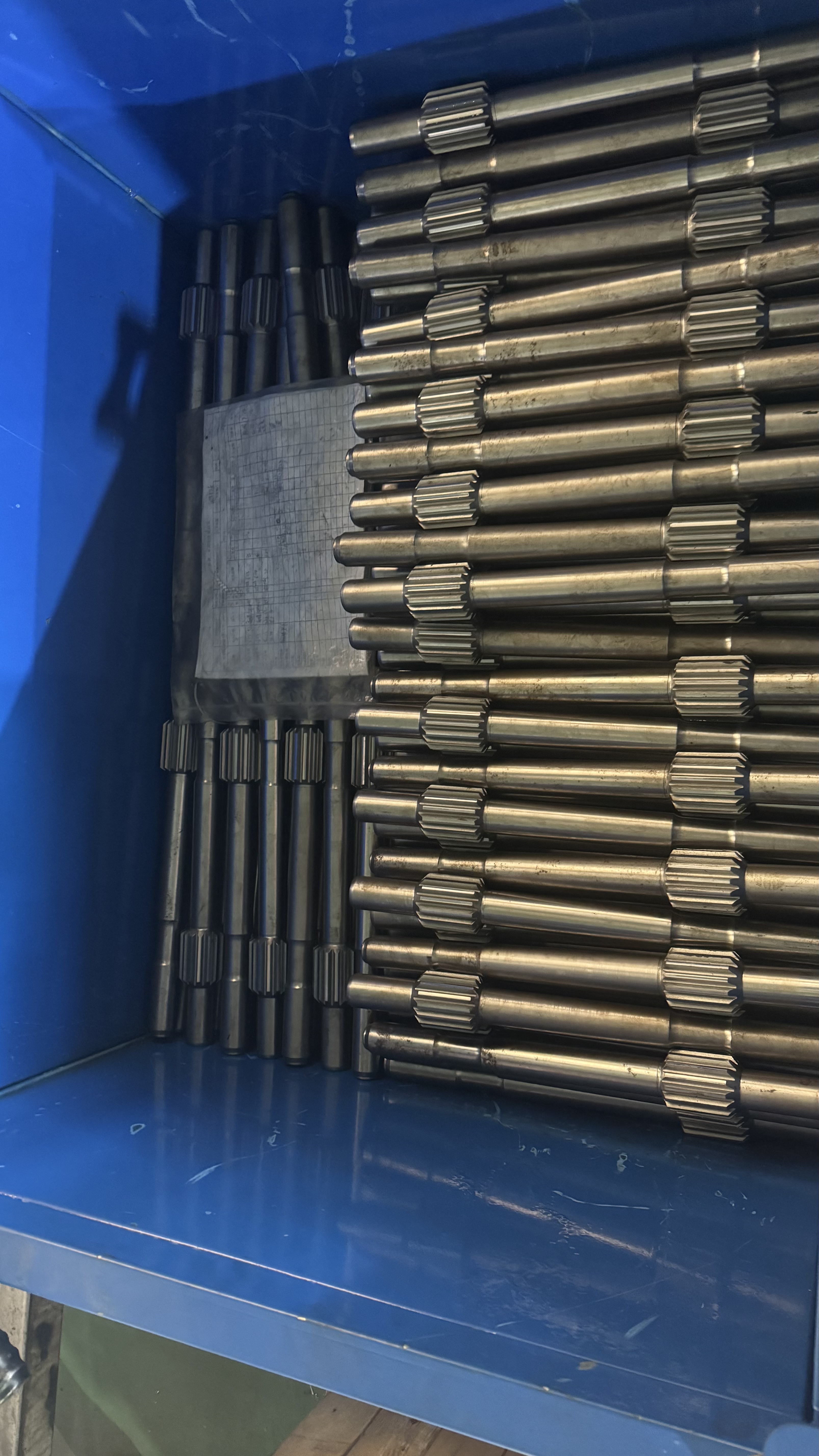

ql60 dth hammer bit

The QL60 DTH hammer bit represents a significant advancement in down-the-hole drilling technology. designed for optimal performance in various drilling applications. This robust tool features precision-engineered buttons made from premium-grade carbide, strategically positioned to maximize drilling efficiency and penetration rates. The hammer bit's unique design incorporates advanced flushing channels that effectively remove debris and maintain optimal temperature during operation. With its 6-inch diameter and reinforced steel body, the QL60 DTH hammer bit delivers exceptional durability and reliability in challenging geological conditions. The bit's innovative button pattern ensures even wear distribution, extending its operational lifespan while maintaining consistent performance. Its compatibility with standard DTH hammers makes it a versatile choice for both mining and construction applications. The balanced weight distribution and optimized impact energy transfer contribute to reduced vibration and improved drilling accuracy. Additionally, the bit's specialized heat treatment process enhances its resistance to wear and impact, ensuring sustained performance in high-stress environments. The QL60's advanced air flow system prevents bit freezing and ensures consistent operation even in demanding conditions.