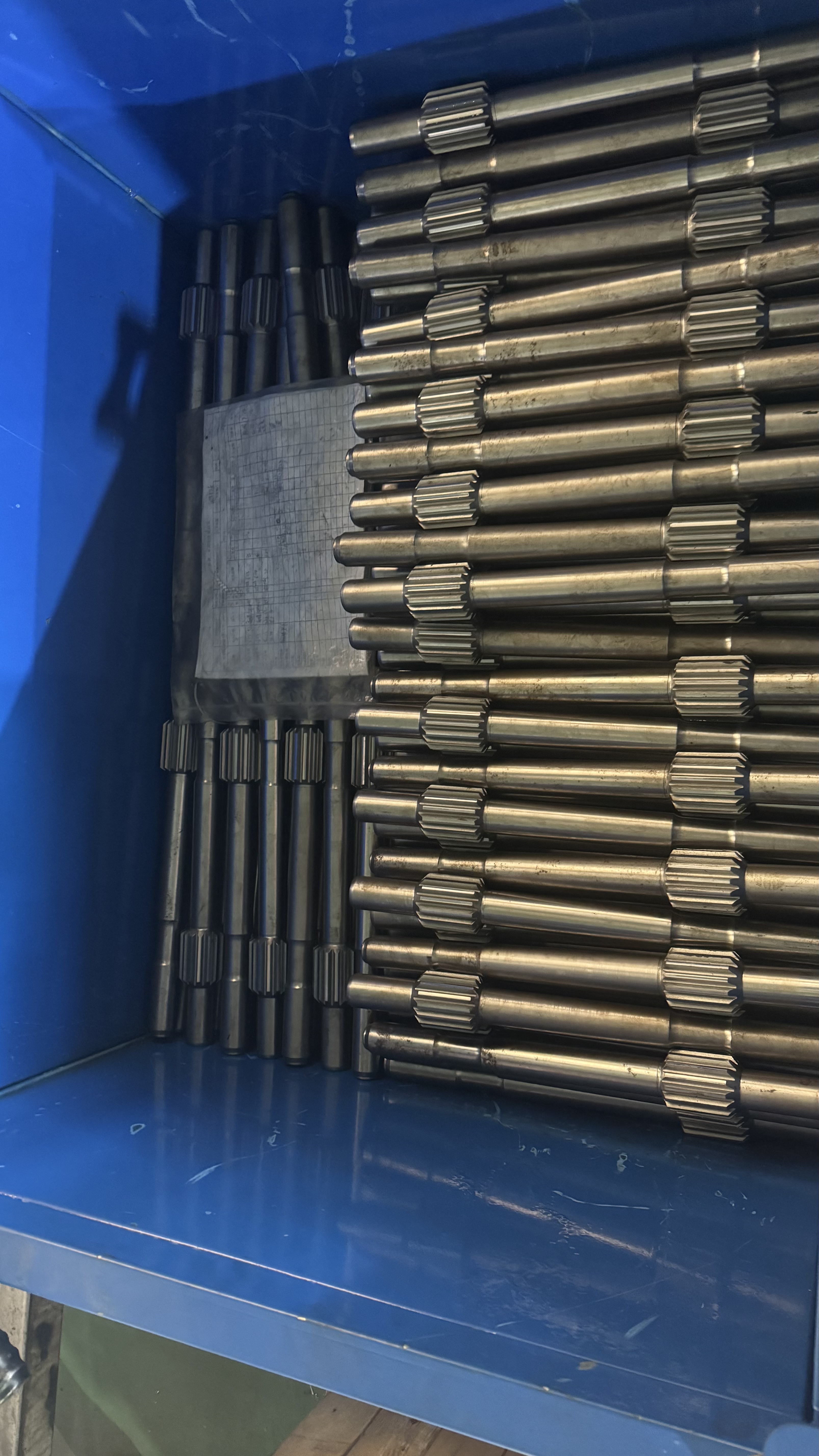

dth hammer bit dhd380

The DTH hammer bit DHD380 represents a cutting-edge solution in down-the-hole drilling technology, engineered for exceptional performance in challenging geological conditions. This robust drilling tool features advanced carbide button inserts strategically positioned to optimize drilling efficiency and maximize penetration rates. The DHD380 is specifically designed with a high-strength steel body and reinforced thread connections, ensuring durability in demanding applications. Its innovative button arrangement provides superior rock crushing capability while maintaining excellent flushing characteristics for efficient debris removal. The bit's specialized face design incorporates enhanced flushing channels that prevent bit flushing and ensure consistent performance even in varying ground conditions. With its precision-engineered air passages, the DHD380 delivers optimal energy transfer from the hammer to the rock face, resulting in faster penetration rates and reduced drilling time. The tool's versatility makes it ideal for applications in quarrying, mining, construction, and water well drilling, particularly in medium to hard rock formations. The DHD380's balanced design reduces vibration during operation, contributing to extended service life and improved drilling accuracy. This hammer bit is compatible with standard DTH hammers and can be easily integrated into existing drilling operations.