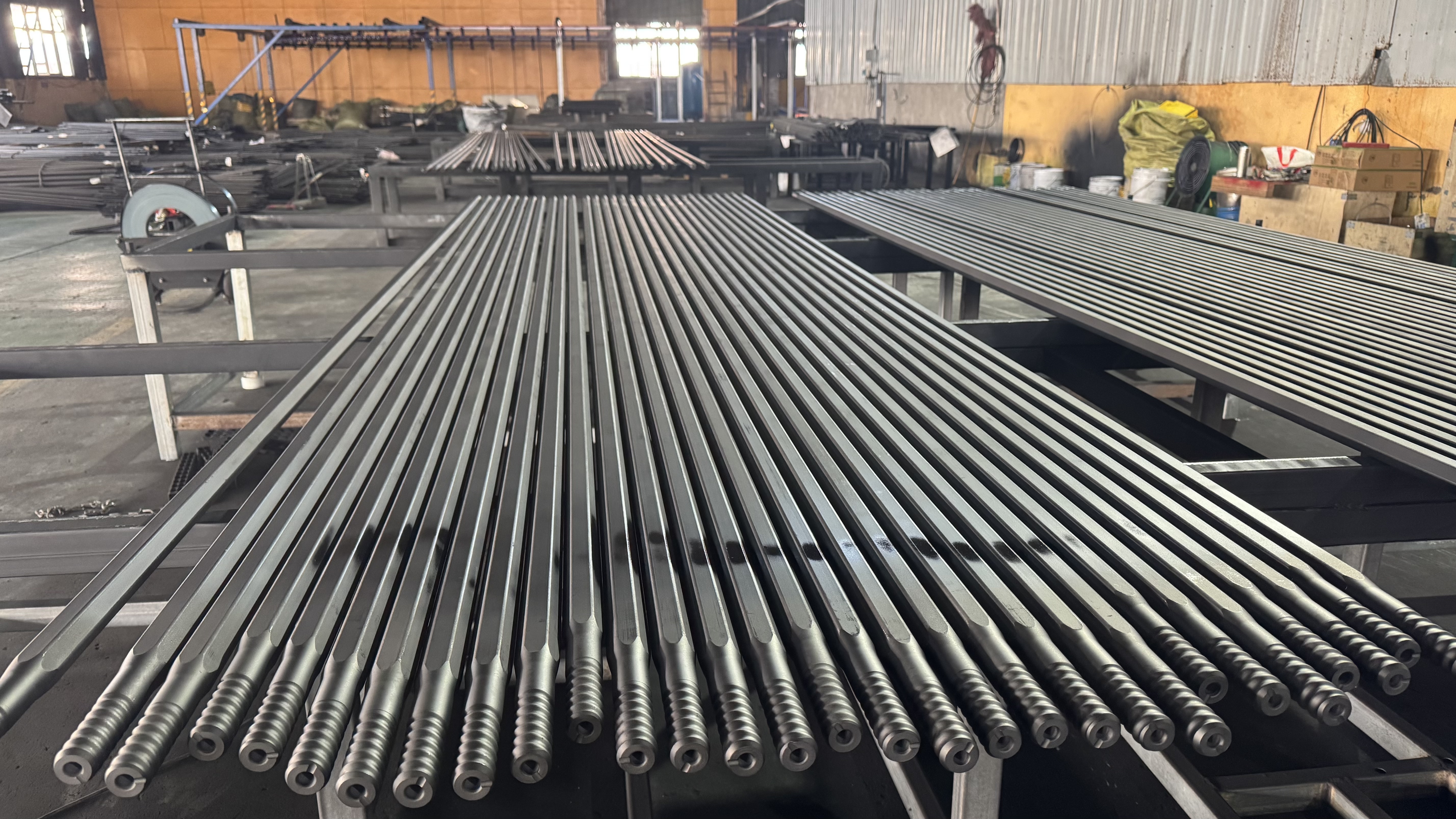

dth hammer bit dhd340

The DTH hammer bit DHD340 represents a pinnacle of down-the-hole drilling technology, engineered for exceptional performance in challenging geological conditions. This robust drilling tool features advanced carbide button inserts strategically positioned to maximize penetration rates while ensuring optimal hole quality. The DHD340 is specifically designed with a high-frequency percussion system that delivers powerful impact force directly to the rock face, resulting in superior drilling efficiency. The bit's unique head design incorporates enhanced flushing channels that effectively remove drill cuttings and maintain proper bit cooling during operation. With its precision-engineered air channels, the DHD340 maintains consistent air pressure distribution, crucial for maintaining drilling performance and extending tool life. The bit's body is constructed from premium grade steel, heat-treated to withstand extreme drilling conditions and resist wear. Suitable for a wide range of applications including water well drilling, mining exploration, construction, and quarry operations, the DHD340 demonstrates exceptional versatility. The tool's innovative gauge protection system helps maintain hole diameter accuracy throughout its service life, while its optimized button placement pattern ensures maximum rock-breaking efficiency.