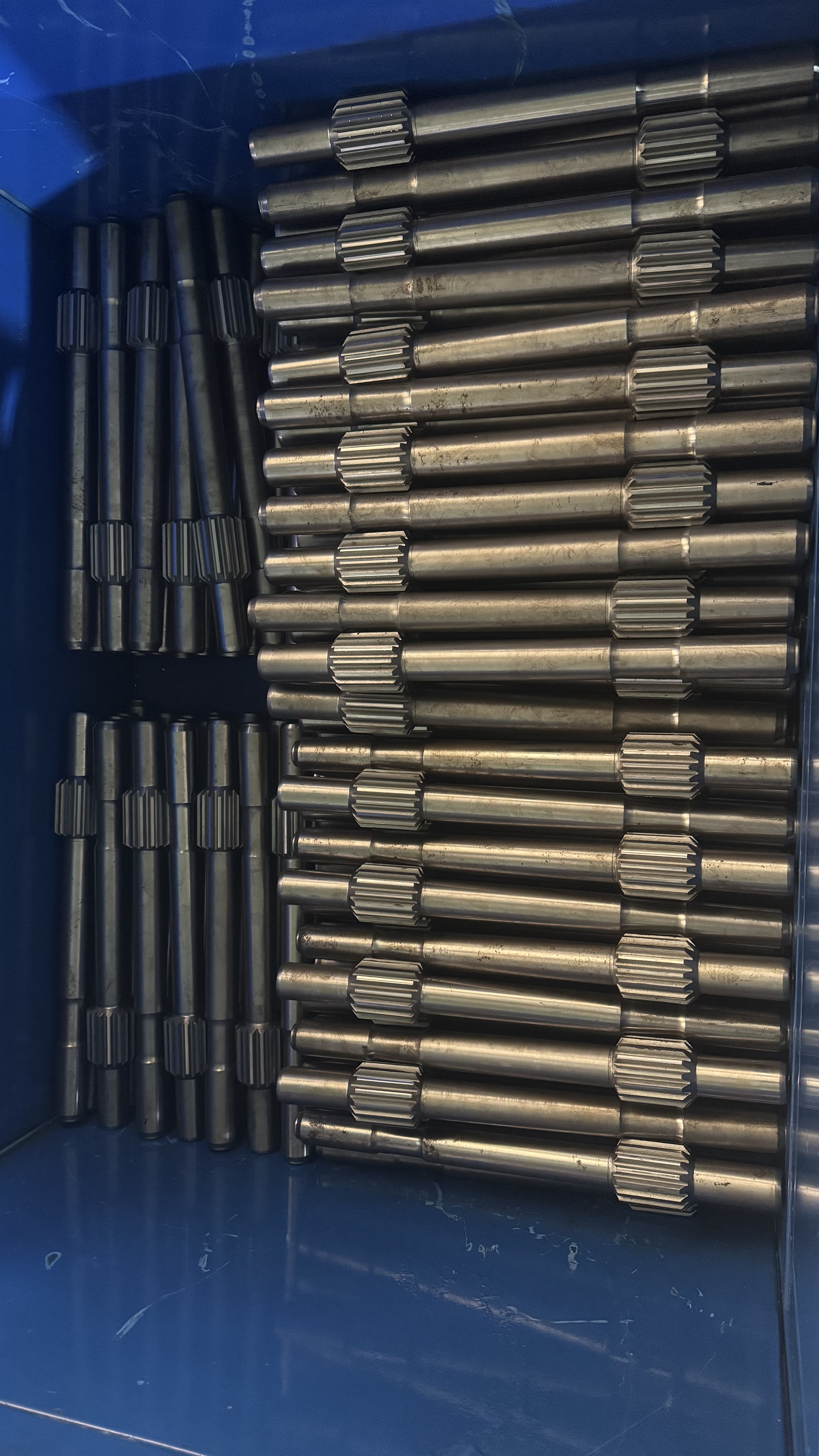

dth drill rods

DTH drill rods are essential components in down-the-hole drilling operations, engineered to deliver superior performance in challenging drilling conditions. These specialized tools consist of high-grade steel construction with precision-engineered threading systems that ensure optimal power transmission from the hammer to the bit. DTH drill rods are designed to withstand extreme pressures and torque while maintaining structural integrity during deep drilling operations. The rods feature advanced wear-resistant properties and are manufactured with specific length configurations to accommodate various drilling depths and applications. They incorporate sophisticated air channel systems that facilitate efficient debris removal and hammer operation, ensuring consistent drilling performance. These drill rods are particularly valuable in mining, water well drilling, construction, and geotechnical applications, where they enable precise and efficient drilling through hard rock formations. The design includes specialized coupling systems that minimize vibration transfer and enhance drilling accuracy, while their balanced weight distribution promotes straight-hole drilling capabilities. Modern DTH drill rods also feature advanced thread designs that prevent premature wear and ensure reliable connections throughout extended drilling operations.