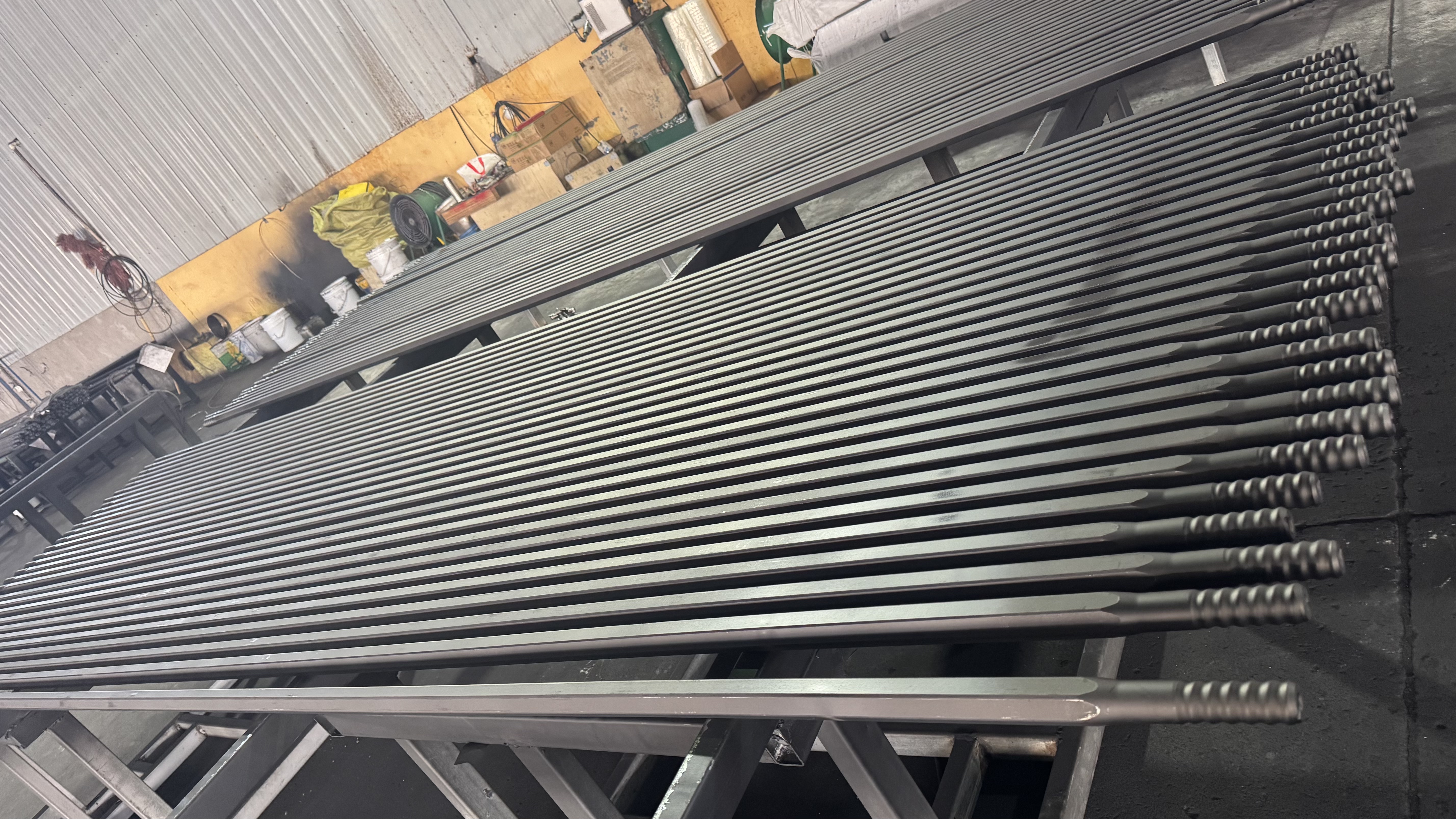

dth hammer drill bits

DTH hammer drill bits represent a pinnacle of modern drilling technology, specifically engineered for deep hole drilling applications in mining, construction, and geotechnical projects. These specialized tools combine robust construction with advanced engineering to deliver exceptional performance in demanding conditions. The bits feature tungsten carbide buttons strategically positioned on the bit face, ensuring optimal rock penetration and extended service life. Operating through a down the hole mechanism, these bits work in conjunction with a pneumatic hammer, utilizing both rotation and percussion to effectively break through hard rock formations. The sophisticated design incorporates advanced flushing systems that efficiently remove debris and maintain optimal drilling temperatures. Modern DTH hammer drill bits are available in various sizes, typically ranging from 3.5 to 24 inches in diameter, accommodating different project requirements. The bits integrate cutting edge metallurgical technology in their construction, featuring heat treated steel bodies and premium grade carbide inserts that withstand extreme drilling conditions. The engineering behind these tools prioritizes both performance and longevity, incorporating wear resistant materials and optimized button patterns that maximize drilling efficiency while minimizing operational costs.