m60 dth mining bit

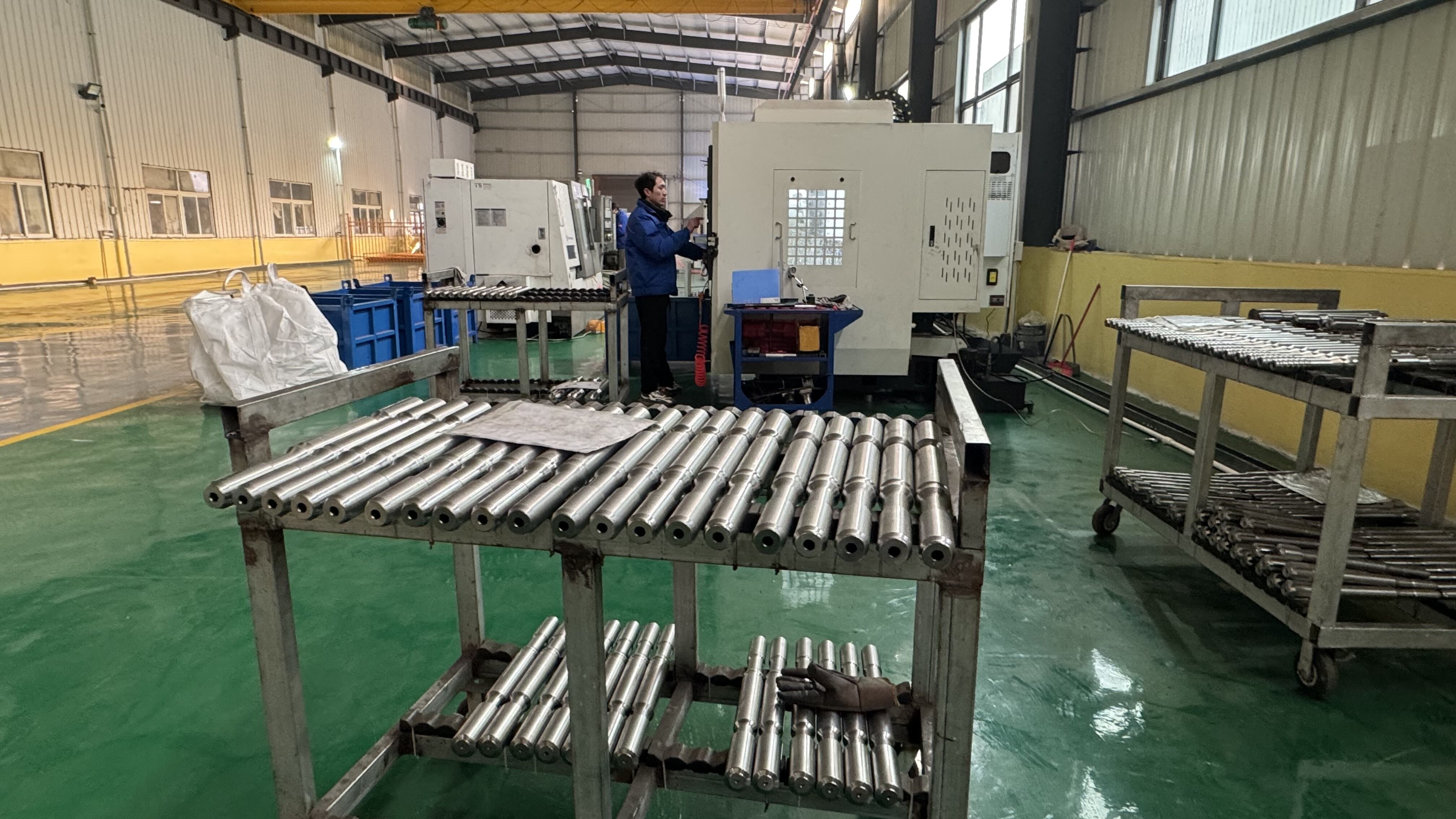

The M60 DTH mining bit represents a cutting-edge solution in down-the-hole drilling technology, specifically engineered for demanding mining operations. This robust drilling tool combines advanced materials science with precision engineering to deliver exceptional performance in various rock formations. The bit features specially designed tungsten carbide buttons strategically positioned to optimize drilling efficiency and maximize penetration rates. Its unique button arrangement ensures even wear distribution, contributing to extended service life and consistent performance. The M60 DTH mining bit incorporates advanced flushing channels that effectively remove drilling debris while maintaining optimal temperature control during operation. The bit's body is manufactured from high-grade steel, heat-treated to achieve the perfect balance between hardness and impact resistance. With dimensions specifically calibrated for mining applications, the M60 can handle high-pressure operations while maintaining structural integrity. The bit's interface is compatible with standard DTH hammers, making it a versatile choice for various drilling systems. Its design also includes enhanced dust suppression capabilities, contributing to safer working conditions and environmental compliance. These technical features combine to create a mining bit that excels in both performance and durability, making it an essential tool for modern mining operations.