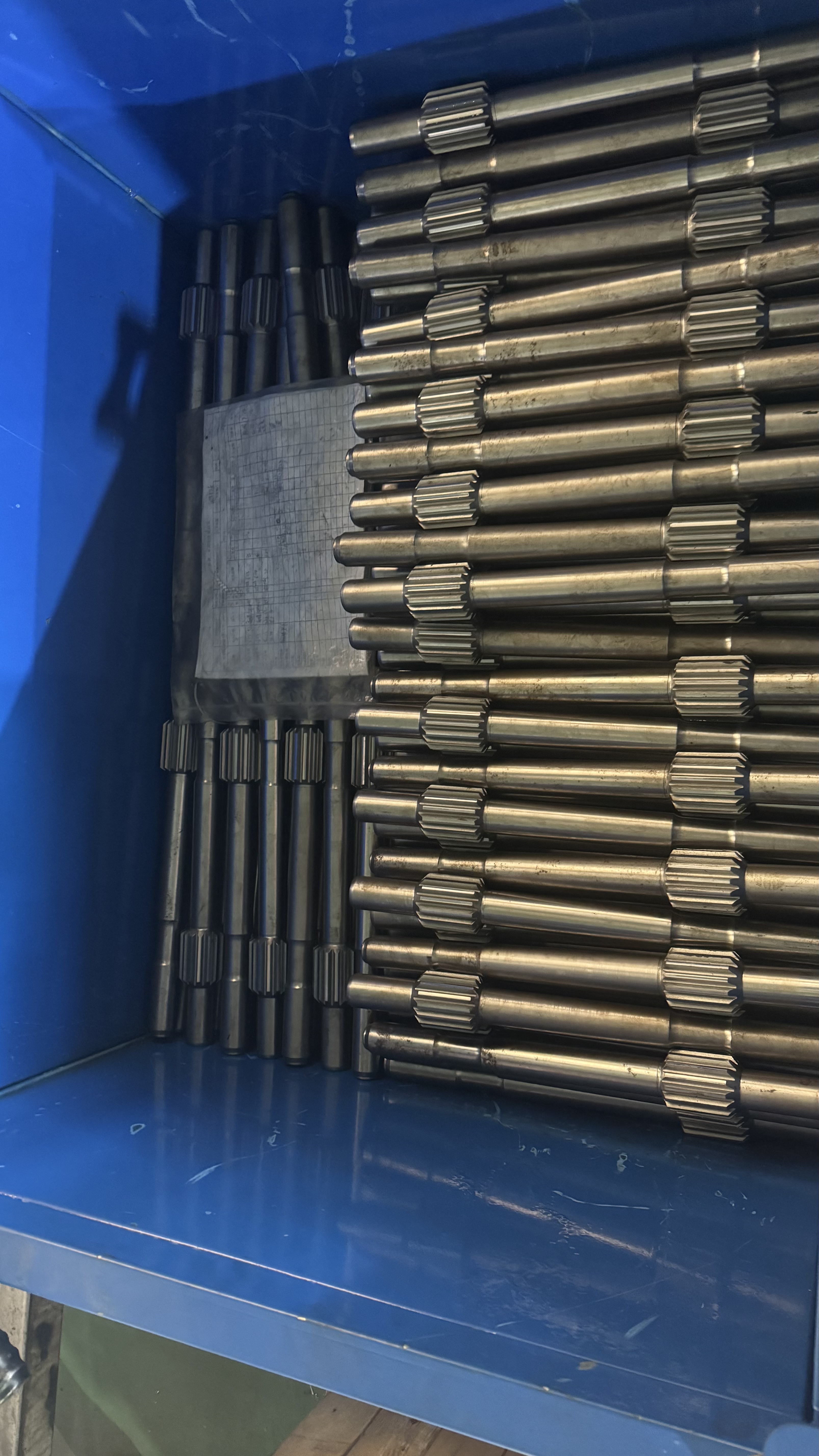

numa125 dth hammer and bit

The NUMA125 DTH hammer and bit represents a cutting-edge advancement in down-the-hole drilling technology, engineered for exceptional performance and reliability in demanding drilling operations. This robust system combines a high-powered hammer mechanism with a precision-engineered bit design, delivering superior penetration rates in various ground conditions. The hammer features an advanced valve design that optimizes air flow distribution, ensuring consistent power delivery and maximum energy transfer to the drilling surface. With its 125mm diameter, the system is perfectly suited for medium to large-scale drilling projects, including water well construction, mining exploration, and geothermal applications. The bit incorporates tungsten carbide inserts strategically positioned to maximize cutting efficiency while maintaining durability in abrasive conditions. The NUMA125's innovative design includes enhanced flushing channels that efficiently remove drilling debris, preventing bit binding and ensuring continuous operation. The system's sophisticated shock absorption mechanism reduces vibration transfer to the drill string, extending component life and improving overall drilling accuracy. Additionally, the hammer's unique chuck design allows for quick bit changes, minimizing downtime and increasing operational efficiency.