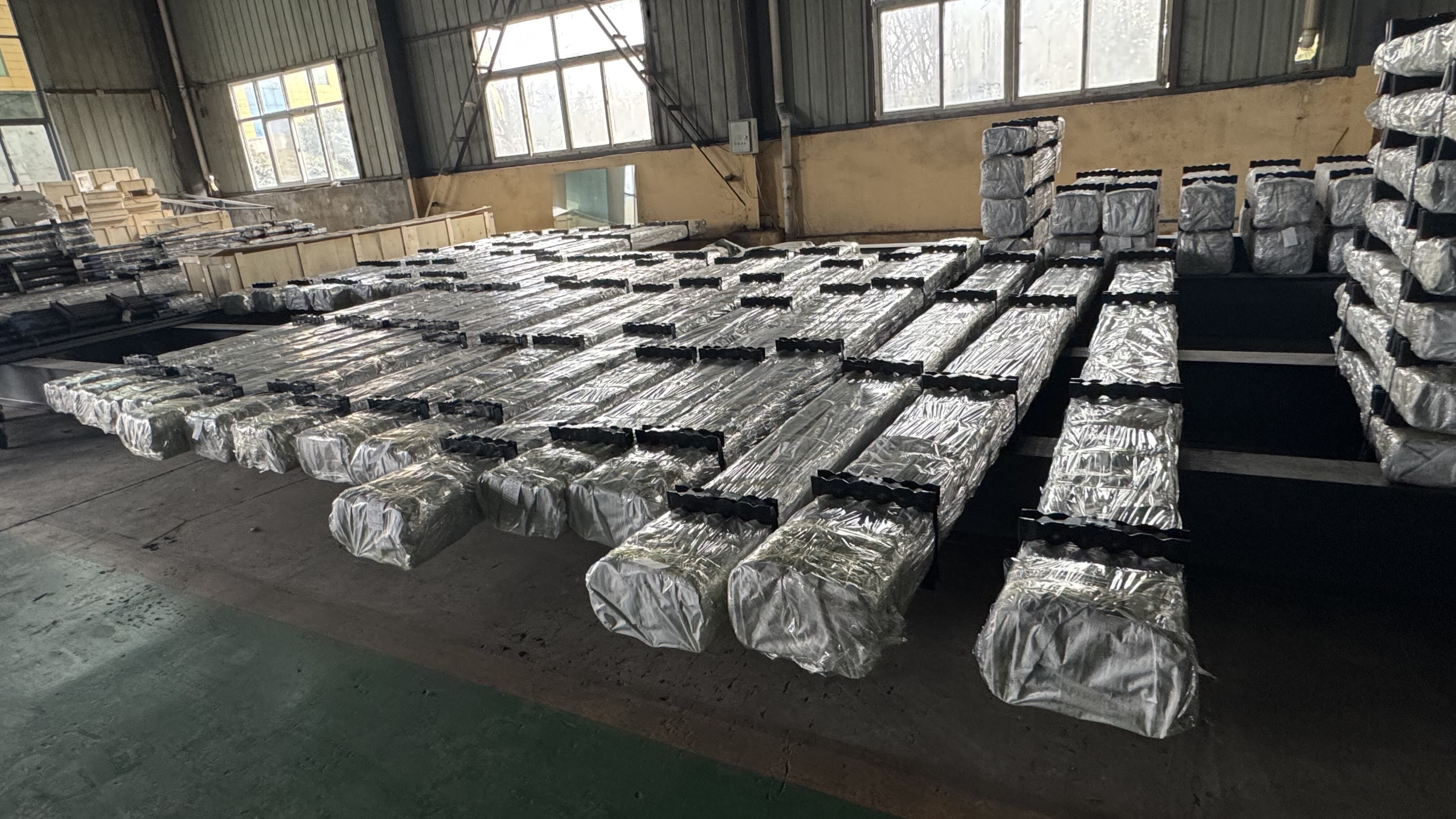

large size hole drilling bits

Large size hole drilling bits are essential tools in construction and mining industries, engineered specifically for creating precise, wide-diameter holes in various materials. These specialized bits are designed to handle demanding applications where standard drill bits would be insufficient. They typically range from 2 inches to over 12 inches in diameter and feature advanced cutting edges made from premium materials such as tungsten carbide or diamond-tipped inserts. The bits incorporate sophisticated cooling channels that efficiently remove heat and debris during operation, ensuring optimal performance and extended tool life. Their robust construction allows them to maintain stability and accuracy even in challenging conditions, while their specialized geometry promotes efficient material removal and reduces vibration. These bits are particularly valuable in foundation work, well drilling, mining operations, and large-scale construction projects. They can effectively penetrate through multiple material layers, including hard rock, concrete, and various soil conditions, making them indispensable for professional contractors and industrial applications.