down the hole hammer drilling

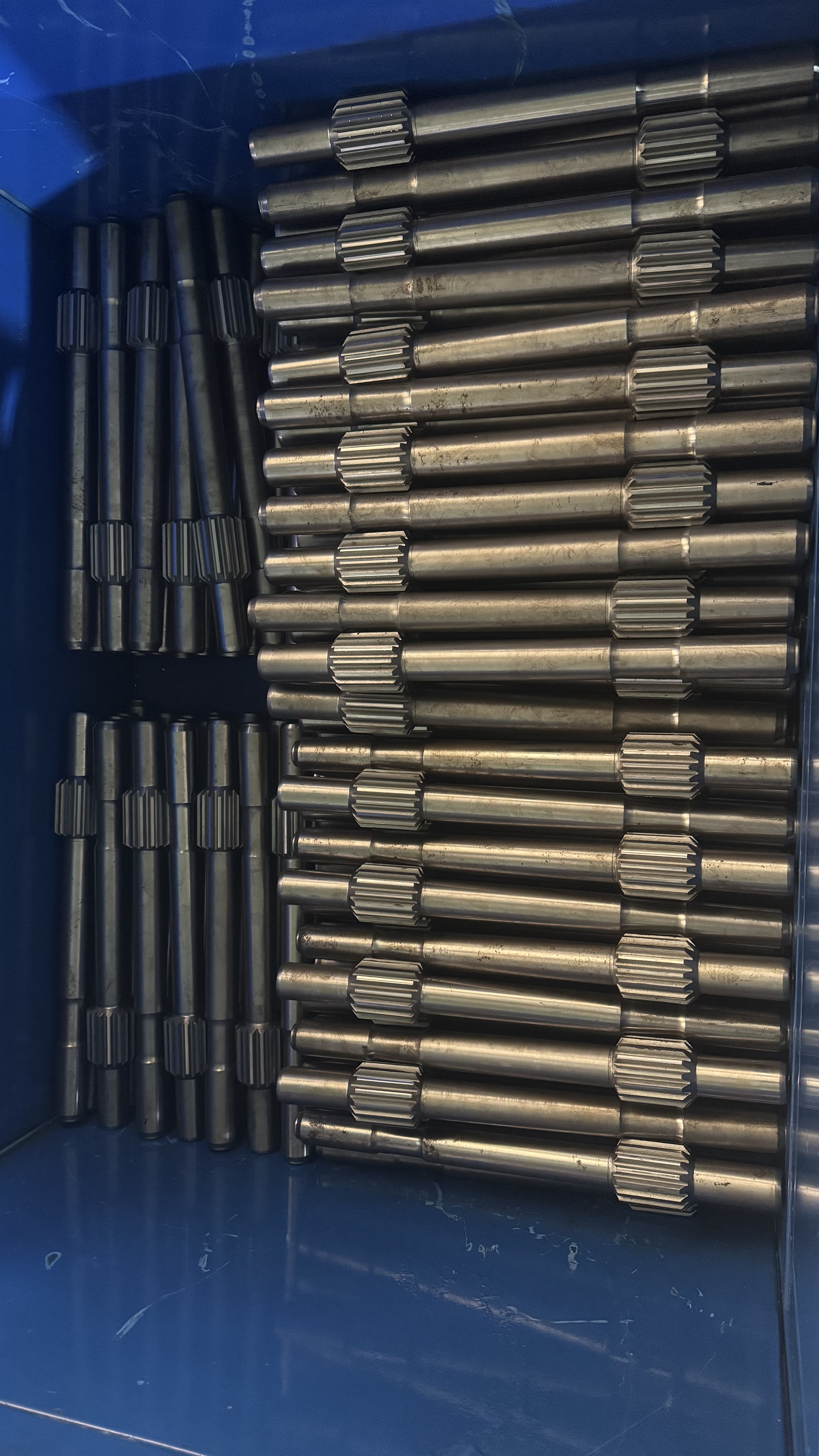

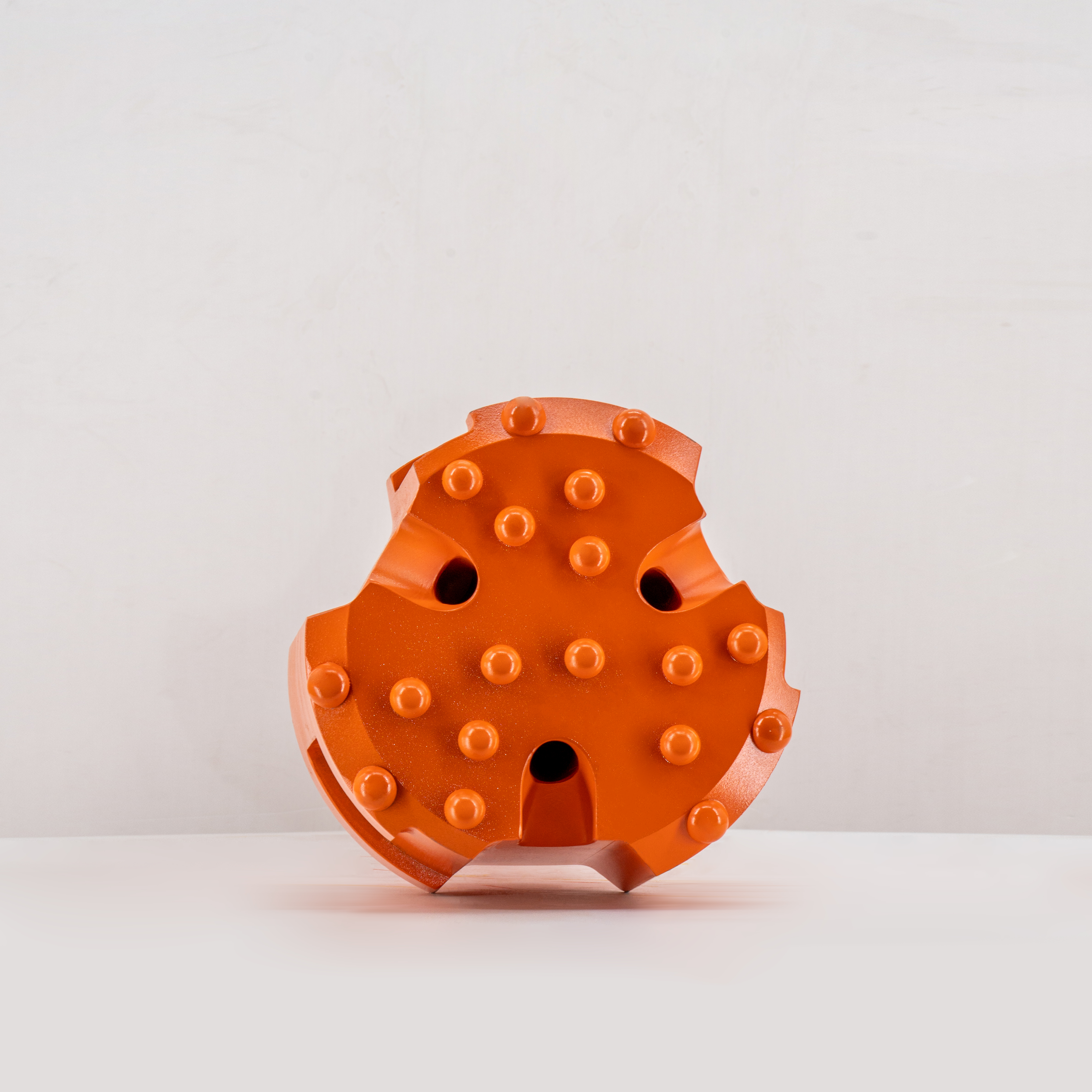

Down the hole hammer drilling represents a highly efficient drilling method that combines percussive force with rotational motion to penetrate hard rock formations. This innovative drilling technology utilizes a pneumatic hammer positioned at the bottom of the drill string, directly above the drill bit, maximizing energy transfer efficiency. The system operates by delivering rapid hammer blows to the drill bit while simultaneously rotating, creating a powerful cutting action that effectively breaks through even the most challenging geological formations. The hammer mechanism is powered by compressed air, which also serves to clear debris from the hole during operation. This drilling method excels in applications requiring deep holes in hard rock, such as water well drilling, mining exploration, and construction projects. The technology incorporates advanced design features including tungsten carbide button bits, high pressure air systems, and precision engineered hammer components that work together to ensure optimal drilling performance. Modern down the hole hammer systems often include sophisticated monitoring capabilities that help operators maintain ideal drilling parameters and troubleshoot potential issues in real time.