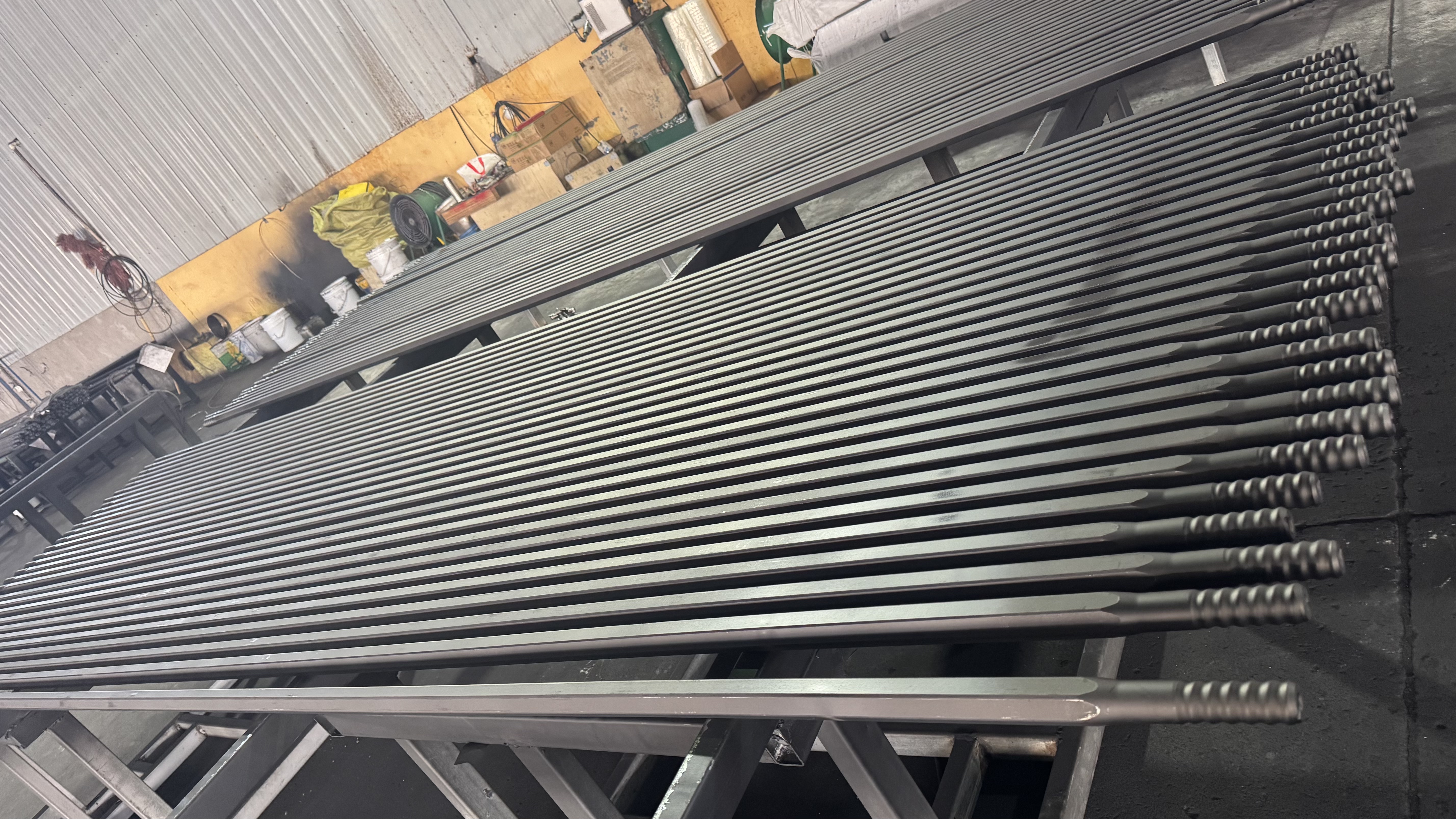

dth rock drillling bit

The DTH rock drilling bit is a sophisticated piece of drilling equipment designed specifically for downhole drilling operations in various geological formations. This essential tool combines advanced engineering with robust materials to deliver exceptional drilling performance in challenging conditions. The bit consists of multiple components, including tungsten carbide inserts, air channels, and a specialized body design that enables efficient rock penetration and debris removal. Operating on the principle of percussive drilling, the DTH rock drilling bit works in conjunction with a hammer to deliver powerful impact forces directly to the rock face. The bit's design incorporates strategically placed buttons or inserts that create the cutting surface, while internal channels facilitate the removal of drill cuttings through compressed air circulation. This technology is particularly effective in hard rock formations, where conventional drilling methods may struggle. The bit's versatility makes it suitable for various applications, including water well drilling, mining exploration, construction, and quarrying operations. Modern DTH rock drilling bits feature enhanced wear resistance, optimized button placement for maximum cutting efficiency, and improved flushing capabilities that extend their operational lifespan and maintain consistent performance throughout the drilling process.