borewell hammer bit price

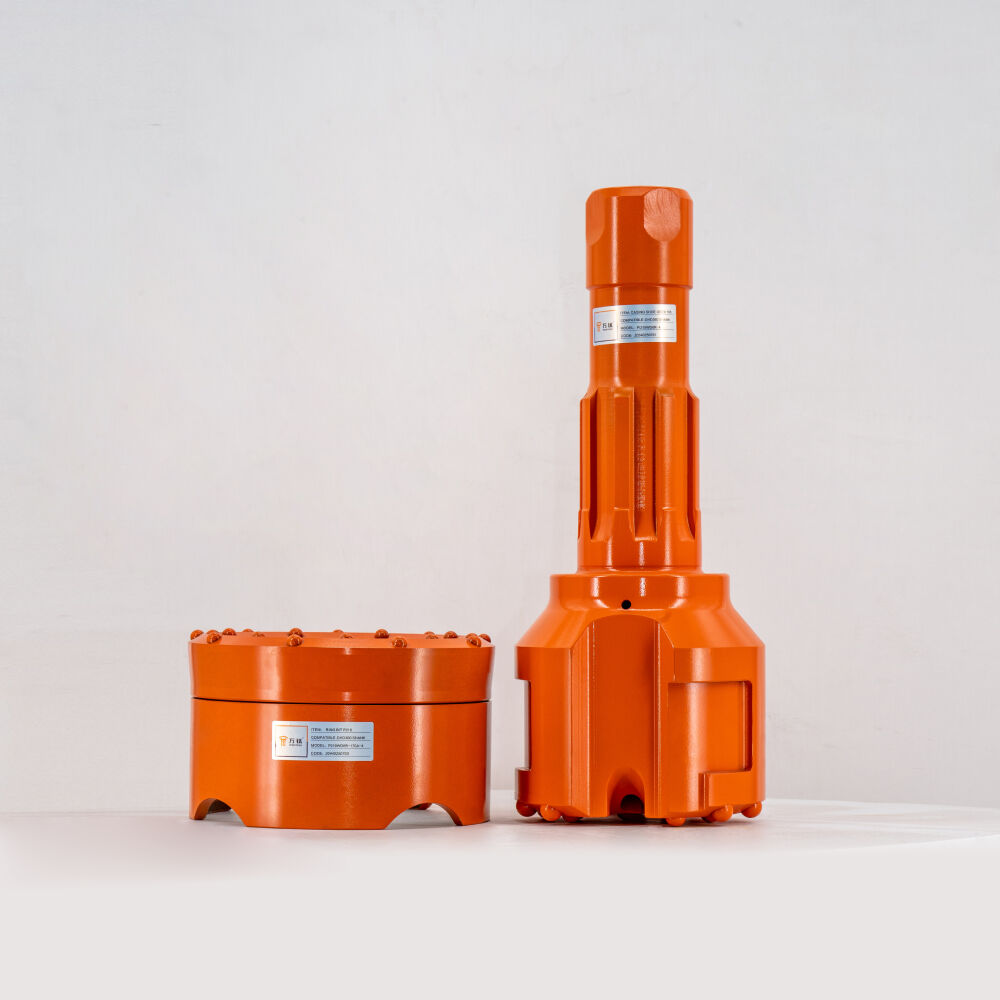

The borewell hammer bit price represents a crucial investment consideration in the water well drilling industry. These essential tools, designed for both hard and soft rock formations, combine durability with cutting-edge technology to deliver optimal drilling performance. Typically ranging from $500 to $3000 depending on size and specifications, borewell hammer bits feature tungsten carbide buttons or inserts that provide exceptional wear resistance and penetration rates. The price variation reflects factors such as diameter size (commonly 4 to 12 inches), button configuration, material quality, and manufacturer reputation. Modern borewell hammer bits incorporate advanced air circulation systems that efficiently remove drilling debris while cooling the bit during operation. The pricing structure often correlates with the bit's capability to maintain consistent performance in varying geological conditions, with premium models offering enhanced features like optimized button placement and reinforced body construction. Manufacturers usually provide warranty coverage and performance guarantees proportional to the price point, ensuring customers receive value commensurate with their investment. When evaluating borewell hammer bit prices, it's essential to consider the total cost of ownership, including expected lifespan, maintenance requirements, and potential productivity gains.